|

If you are designing new product, especially if you project similar product series, it is convenient to reuse existing parts or assemblies. Integrated Autodesk Inventor or operating system tools cannot easily solve this problem. Inventor's integrated assembly copying function can work with assembly's components only. They not allow you to automatically assign drawings or presentations to copied components. You can't select component group and modify it. You must wait until assembly is fully loaded into Autodesk Inventor before you can make modifications with assembly components. You cannot select a group of files and apply automated renaming tools, for example add suffix or prefix to assembly components name and so on. Assembly Copier quickly solves this and many other problems. |

Assembly Copier can easily maintain links between Autodesk Inventor files.You can copy or reuse files, using integrated renaming and coding tools and directly edit file properties. Also you can split modeling process in two stages:

• when components are named using simple and easy understandable names,

• and when components get coded names.

This is useful when you in the beginning of design create assembly and name components in his functional meaning. For example: "leg", "rod", "cover" etc. Inventor these names applies to filename of component when you save it to disk. Part Numbers gets these names as well. When you start assembly renaming/copying then it is very convenient to move functional names in to the component description field using Column replace to column tool. In such way you don't lose functional names of components.

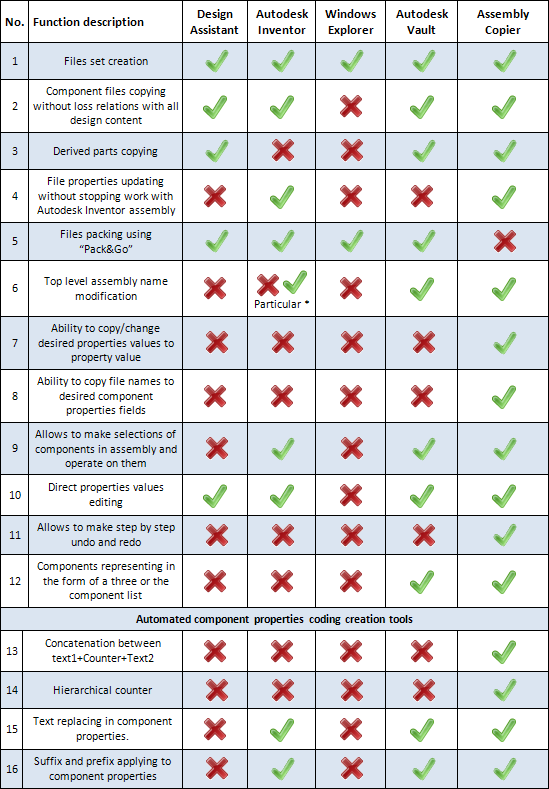

Assembly Copier comparison with other products:

* You must create a dummy assembly and insert top level assembly in to it