To open the Mill command, go to:

Woodwork CAM -> Mill ![]()

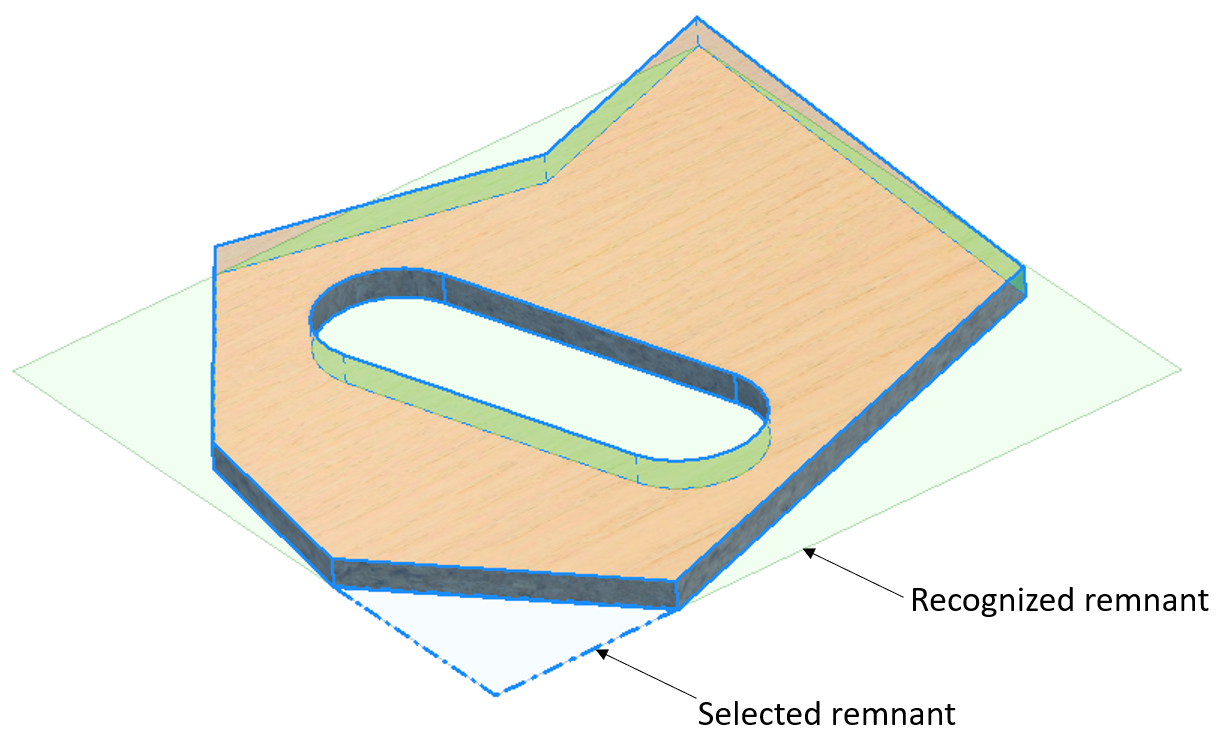

A dialog window will appear once you open the command.

To successfully run the command, the user should follow a certain sequence for specifying data. Below you will find the description of the control of the command in the sequence that needs to be followed when performing tasks in the mill command window.

|

Both a surface and a sketch can be selected as a milling object. The setting of the tool’s position will differ depending on the selected geometry type. Let us examine both cases one by one.

Setting the tool position when the milling object is a part surface

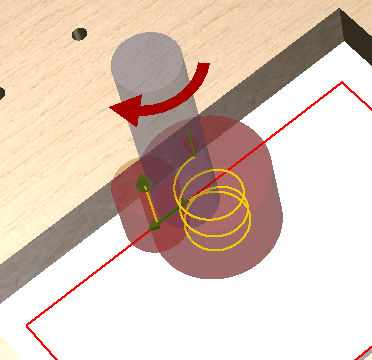

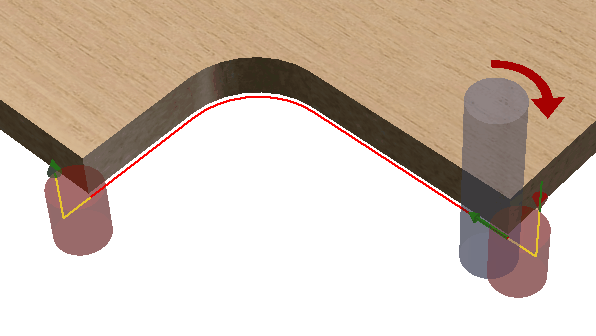

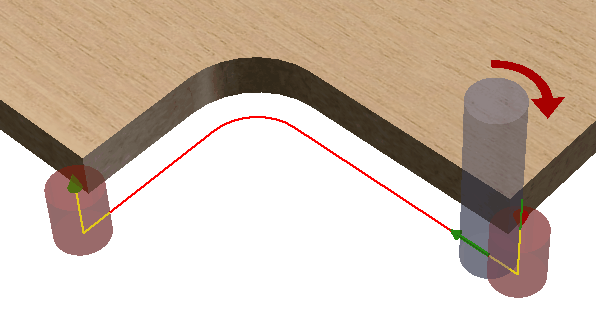

The rotation direction of the spindle is stable and depends on the shape of the mill tool installed in it. The mill tool, while moving with respect to the surface, should do so in the manner so as to avoid damaging the part body. Therefore, the trajectory of the tool must be set off by the tool Radius with respect to the surface. Thus, when changing the side of the contour on which the tool will pass, the direction in which the tool travels along the contour also changes. Also, the setting of the side of the tool with respect to the contour also changes the milling mode:

If the user does not select on which side of the surface the tool should pass, the Mill command will then automatically set the passing direction for Climb milling. This type of milling poses less risk to cut off a wood component during the milling process. However, there occur processing situations where the user may need to apply a milling method where the feed direction of the cutting tool is opposite to its rotation (Conventional Milling). For this purpose, the user has an option of changing the tool position with respect to the surface being milled.

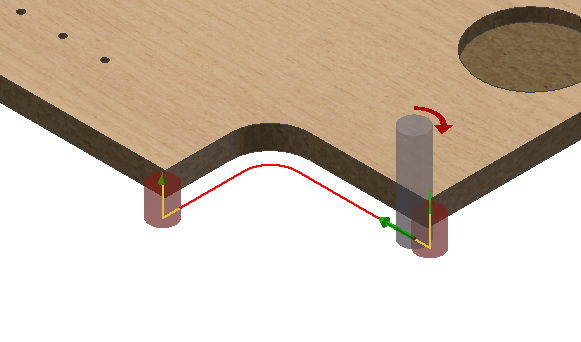

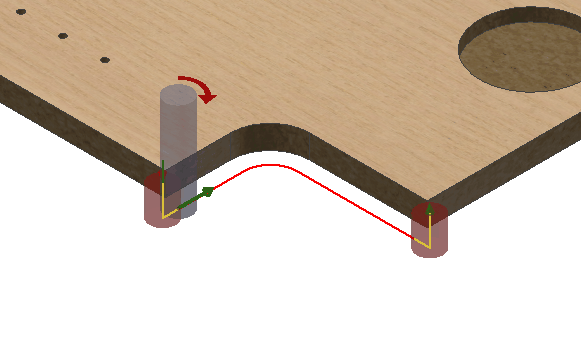

Setting the tool position when the milling object is a sketch As already mentioned, reference geometry may also consists of 2D sketches drawn by the user. Unlike the above requirement that the mill tool, while moving with respect to the surface, must do so in the manner so as to avoid damaging the part body, in the case of a sketch, this requirement is not applicable because the geometry of the sketch does not carry information about where the part body is located. Due to this reason an additional option appears allowing the user to Reverse the direction in which the tool travels along the contour without changing the side of the tool with respect to the contour. Thus, in the case of a sketch, you can not only set which side of the sketch line the tool should pass but also reverse the direction in which the tool travels along the contour. Also, with respect to the contour expressed as a sketch, one can request that the tool moves along the contour at the centre of the tool without setting off the tool trajectory to the side. In other words, we can assume that a drawn sketch expresses the tool trajectory itself rather than the desired contour. We get following cases of passes.

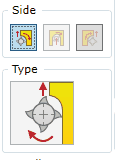

Setting the contour processing direction in the dialog window

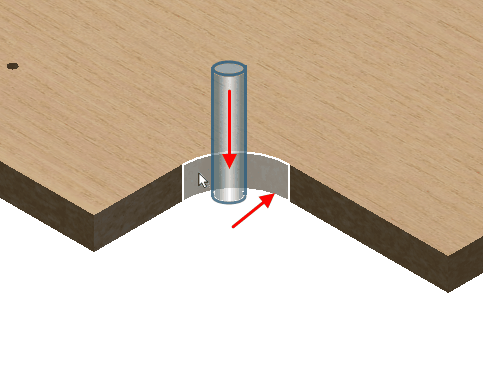

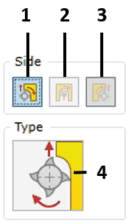

As stated above, it becomes clear how the setting of the tool position where the reference geometry is a surface is different from the case where the reference geometry is a sketch. Below are provided two images of the Mill operation’s dialog window which appear depending on which reference geometry is used.

Reference geometry is a surface. Two options are available:

1. The position of the tool to the left of the surface. 2. The movement of the tool along the centre in this case is deactivated. 3. The position of the tool to the right of the surface. 4. The window displays, at a greater zoom level, which milling type is used: the direction of cutter rotation is different than the feed motion (Conventional) or the direction of cutter rotation is the same as the feed motion (Climb).

Reference geometry is a sketch. Two options are available:

1. The position of the tool to the left of the surface. 2. The movement of the tool along the centre. 3. The position of the tool to the right of the surface. 4. The window functions as a button and once you click on it, the movement direction around the sketch is Reversed.

|

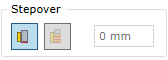

Sets the landing method of the tool to the starting point of the trajectory. There are two landing options available:

Later these parameters can be edited using the side browser. You should bear in mind that, in case the value for the approach to the trajectory is set as the Ramp landing, the above options are not applicable and the tool in this case will enter the material by landing in a sloped line downward to the first point of the trajectory.

|

|

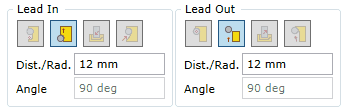

Turns on or off stepover contour milling and allows the user to set the stepover distance.

If the stepover is on, you can indicate the depth of one layer. Note. The functioning of this option is not visualized in the graphic view of the trajectory, but this option will have an impact on the generation of the final CNC program. You can also see this when a simulation of the created CAM technology is running.

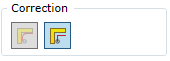

|

Each method has its own strengths and weaknesses. For example, the tool correction which is usually performed in the machine is rather simple and once faced with a complex contour it is not capable of processing the situation or interprets it incorrectly. However, when designing CAM technology, tasks are performed with approximate tool sizes. For example, the system calculates that the mill tool is 20 mm in diameter, while in fact its diameter (after it is sharpened) may be 19.2 mm. In this way, if we trust the calculations of the CAM system, we may have accuracy problems. On the other hand, the machine contains accurate tool data, thus if the correction is performed within the machine, you can then expect that a required accuracy will be maintained. The user has an option to select the way of indicating a tool milling trajectory: as a trajectory of the tool center or as a mill contour.

|

|

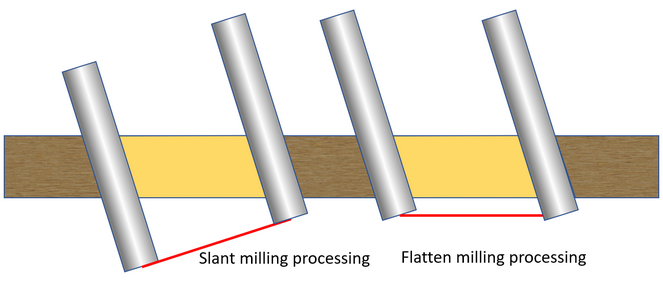

Slanted milling can be performed in two ways:

▪The tool trajectory is inclined and lies in its own defined Custom Plane. ▪The tool trajectory is flattened to the Top Plane and the tool itself moves in an inclined position.

|

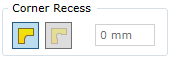

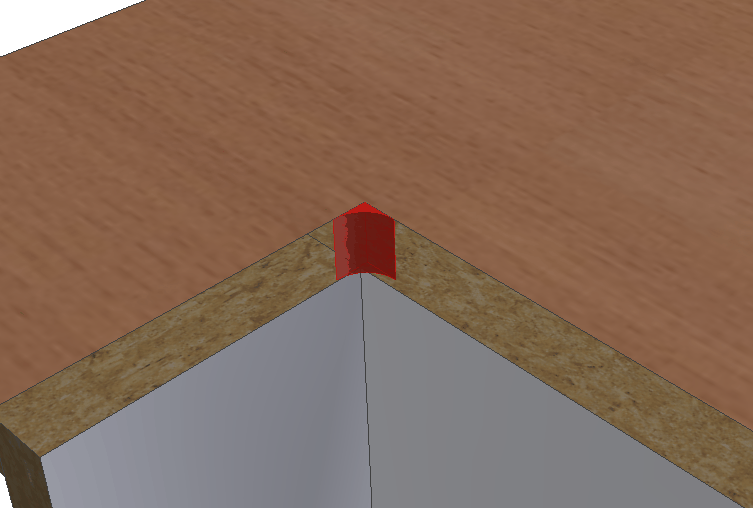

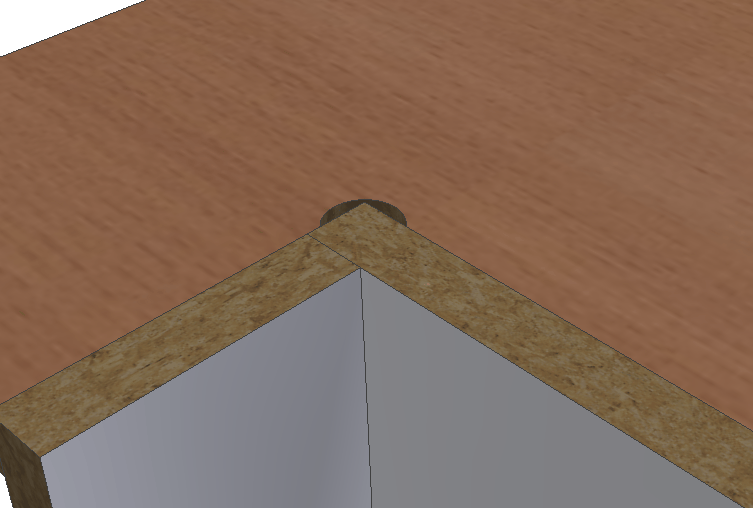

Designers often do not worry about the precision of furniture design. Sometimes there occurs situations where such a discrepancy translates into non-assembly which results after processing contours with the CNC machine. To solve this problem, there is an option which creates an additional mill movement in the recess trajectory corners. This movement helps to mill a pocket and in this way creates a part shape which ensures the joint as shown in the figure below.

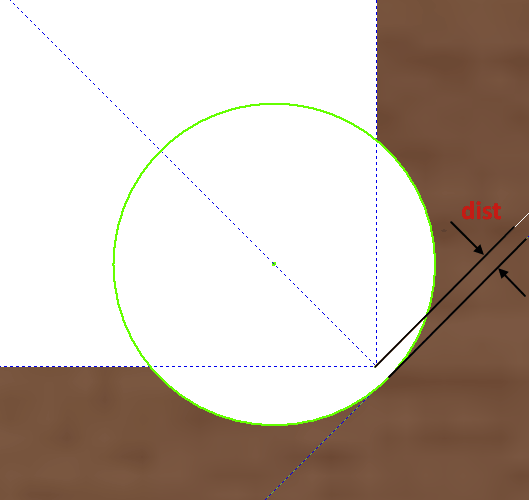

In the relevant field, you may indicate the depth to be reached by the mill tool from the corner (see fig. below).

|

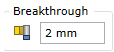

When milling contours that go right through the part body, they need to be milled by plunging the mill tool deeper than the bottom of the milled contour. The next parameter called Breakthrough is used for setting this value. One should bear in mind that this parameter does not apply to contours that do not go right through the part body. In this case, the mill tool will pass along the bottom.

|

Setting the oversize for milling. You should bear in mind that a contour will always be calculated in a given situation as if the part is without covers. If the milling operation is set up as a compound operation with a sub-operation of the rest milling operation, in this case the oversize tolerance is combined with the residual milling tool tolerance.

|

|

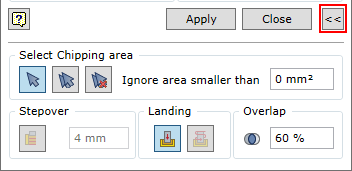

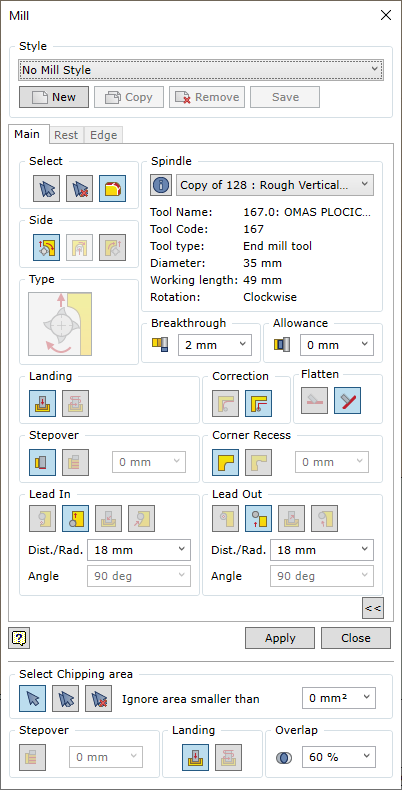

Milling contours produces large Remnant pieces. In classical machines, these remnants fall to the bottom of the machine body where they are collected and removed for disposal. However, in vertical machines or in bottom-working machines, this sequence of events is not appropriate. These remnants have to be cut into shavings. For such cases, the milling command has an additional drop-down section which identifies the areas of such remnants and, at the user’s request, cuts them into shavings.

When the section is opened, automatic identification of the remnant areas takes place. The user has the possibility to create a set of such areas and to set a chipping operation for them.

|