The general settings are accessed in the tab ![]()

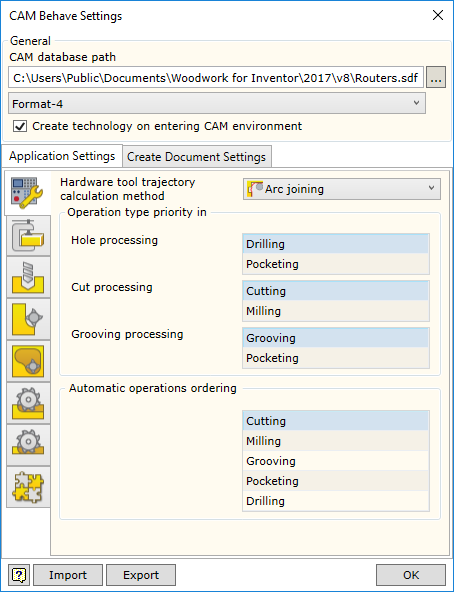

Setting the method of calculation of the bottom trajectory of the milling tool. Three options are available:

|

|

Operation type priority in |

When creating the CNC technology, ambiguous situations occur, where the same part form can be obtained by completing different operations. For example, part corners can be cut using a saw or milled with an end mill. To avoid such uncertainties, operations are arranged in the order of priority. In the above ambiguous situations, CAM solver will choose the operation with a higher priority level. Operation priorities are specified separately for: ▪Hole processing ▪Cut processing ▪Grooving Processing Position of the operation in the line of priority can be changed by selecting the operation with the cursor and dragging it to the desired position within the table. |

In the created CNC technology, operations can be arranged in a defined order. The user can change this order by dragging the selected operation to the desired position within the table. The order of arrangement of operations does not necessarily correspond to the order of priority of operations. This order is also used to automatically arrange operations, when this is requested by the user, or with manually created trajectories. For Nesting Router machines, additional Route Nesting operation is provided in the operations ordering process. |