Part workpiece clamping settings are available in the tab ![]()

Clamping of a part in a machine depends on numerous factors, original settings and restrictions. By changing the original settings, the user can affect the rating of clamping options performed by CAM solver.

There are two tabs used to configure clamping settings:

This tab is used to configure the general parameters necessary to create a clamping option.

The following parameters can be specified:

|

When deciding on the orientation of a part in case of a specific clamping option, various requirements have to be taken into account and, sometimes, these requirements can be contradictory.

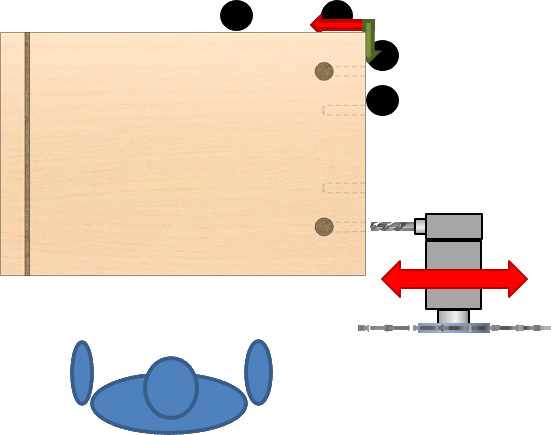

For example, as shown in the figure above, grooving requirement conflicts with the request to drill holes, etc. CAM solver selects all the available clamping options. Each clamping option is rated based on the specified criteria and scored accordingly. Clamping option with highest score is used as a winning option. These criteria are shown in the criteria rating tab.

Before summing up, the score of each criterion is multiplied by a factor specified by the user. This allows the user to change the weight of the criteria and affect the operation of CAM solver. Currently, the following clamping criteria are rated:

By changing the rating factor, the user can increase the weight of individual criteria necessary to rate clamping options. If the value of the factor is 0, the criterion will not be taken into account when calculating the score for a clamping option. |

Important. CAM solver will always give priority to clamping options offering fewer processing operations avoiding operations where the external workpiece loop can be trespassed. This is to ensure that, once flipped over, the part has base surfaces and does not require procedures with special clamping. The reverse order applies to CNC Nesting machines. Here, priority is given to clamping options with the highest number of processing operations, including the processing of the external loop.