Configuration command for the behavior of the CAM solver is opened from the part editing environment of Autodesk Inventor and moving on to the Woodwork CAM module:

Opening the Command

Woodwork CAM -> CAM Behave ![]()

|

CAM database path |

Specifies a path to the database of CNC machines. |

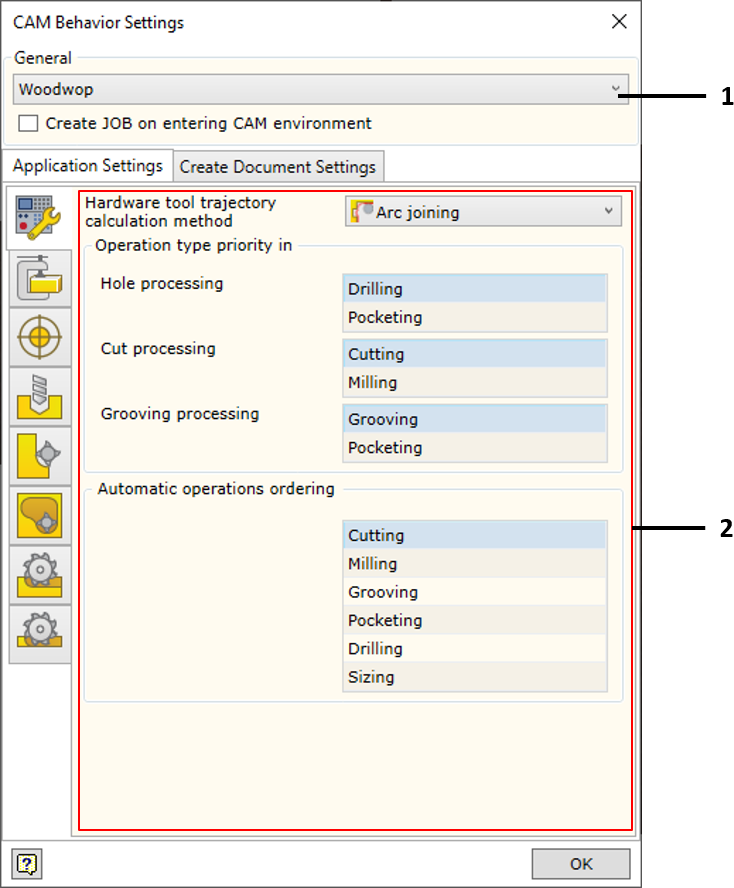

1 |

Machine selector |

Allows selecting a machine for which behaviour parameters of CAM Solver are set. Please note! The most common mistake is when users configure behaviour for one machine and hope that it will be taken into account when generating a CNC technology for another machine. |

|

Create JOB on entering CAM environment |

When opened, CAM environment activates automatic creation of a JOB. The job will be automatically created only if the CNC technology is empty at the time of opening the CAM environment. The machine used in the automatic creation of the job (as one of the properties of the material) is specified in the Material Editor. To read more, click here.

|

2 |

Editing space for CAM behaviour parameters |

This space is used to edit CAM behaviour parameters. The content of this space changes depending on the selections made in side tabs.

|

|

Application Settings |

This tab is used to edit and save the general CAM behaviour settings.

|

|

Document settings |

This tab is used to edit and save CAM behaviour settings for the current component. The component can be both an assembly and an individual part. If such settings are defined for the component, the tab is marked with additional sign. |

|

General Settings |

A tab containing general settings for automatic generation of CNC technologies. For more information, click here. |

|

Part Clamping Settings |

A tab containing settings for the clamping of the part in the CNC machine. For more information, click here. |

|

Sizing operation settings |

The tab containing sizing operation settings. More information is available here.

|

|

Drilling Operation Settings |

A tab containing drilling operation settings. For more information, click here. |

|

Milling Operation Settings |

A tab containing milling operation settings. For more information, click here. |

|

Pocketing Operation Settings |

A tab containing pocketing operation settings. For more information, click here. |

|

Grooving Operation Settings |

A tab containing grooving operation settings. For more information, click here. |

|

Cutting Operation Settings |

A tab containing cutting operation settings. For more information, click here. |

|

Nesting Operation Settings |

A tab containing nesting operation setting. For more information, click here. |