When CAM solver is deciding on the orientation of the part for the automatically created CNC technology, it is important to know:

| ▪ | The status, in which the part is supplied to the CNC machine. |

| ▪ | The coordination system used in the CNC machine used for the processing. |

| ▪ | If different clamping option is required – inversion (where the machine operator flips over the part). The method of calculation of the base point for the next clamping option depends on this. |

| ▪ | The priority of part orientation, because the part can be oriented in several directions. |

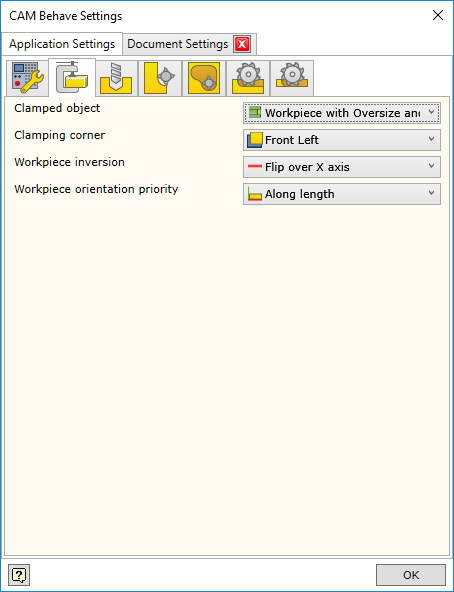

These factors can be defined in the workpiece clamping settings tab.

Clamped object

|

Setting the part status, in which it is clamped in the CNC machine for the purpose of processing. The available options are listed here. |

||||||||

Clamping corner

|

Setting the clamping corner in the machine. For more information, click here.

|

||||||||

Workpiece Inversion |

If processing the part requires several clamping options, once the operations with the first clamping option have been completed, the operator flips over the part and activates the program for the following clamping option. The method of calculation of the base point for the next clamping option depends on this. The following settings are available:

The option used depends on the arrangement of the machine and agreements within the organization.

|

||||||||

Workpiece orientation priority |

Part workpiece can be oriented along its longer or shorter edge. This depends on the arrangement of the machine and agreements within the organization. |

Important. CAM solver will always choose the clamping option with a lower number of processing operations and without contour milling first. This is to ensure that, once flipped over, the part has base surfaces and does not require procedures with special clamping. Moreover, when fulfilling all of the above requirements, CAM solver always seeks to find the position, in which the part is placed in the CNC machine without banded surfaces. This helps to reduce the likelihood of error due to delivery of the part workpiece in a position other than that defined when creating the CNC technology.