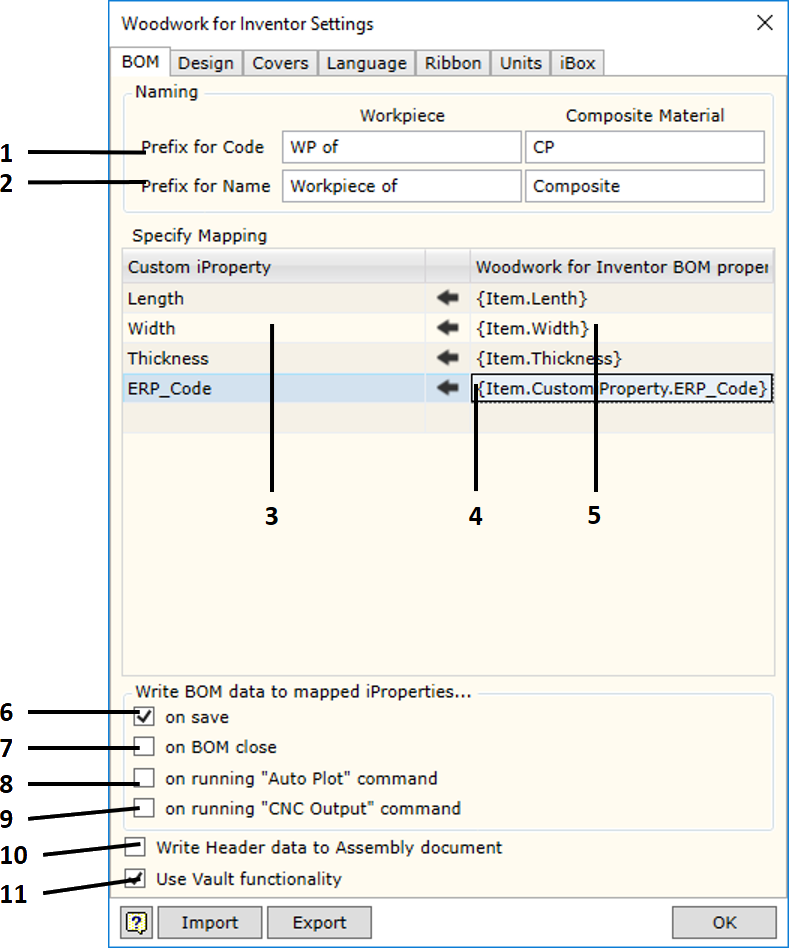

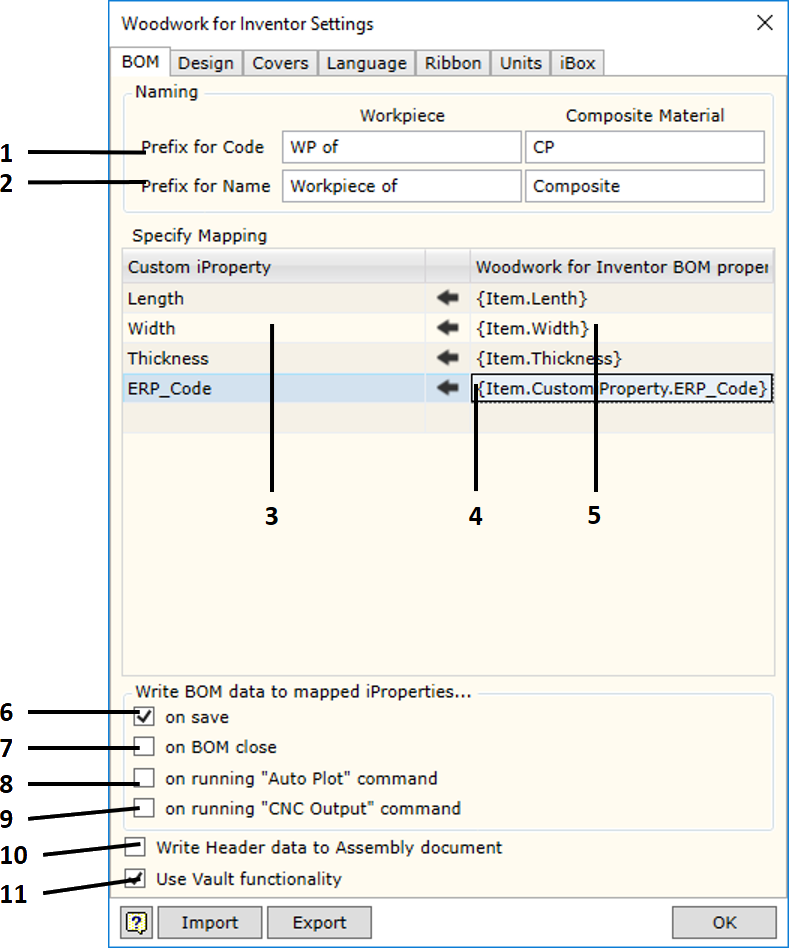

1. Prefix for Code - sets prefix for the code.

| ▪ | Workpiece - field used to indicate a desired prefix for the workpiece code. In Woodwork for Inventor, each part consists of workpieces (click here for more information). These workpieces automatically acquire the same code as that of the part including an additional prefix the meaning of which is entered in the field described herein. |

| ▪ | Composite Material - field used to indicate a desired prefix for the code of the part workpiece glued from other parts. Woodwork for Inventor part workpieces can be designed from several parts consisting of workpieces (click here for more information). These workpieces automatically acquire the same code as that of the material assigned to it including an additional prefix the meaning of which is entered in the field described herein. |

2. Prefix for Name - sets prefix for the name.

| ▪ | Workpiece - field used to indicate a desired prefix for the workpiece name. In Woodwork for Inventor, each part consists of workpieces (click here for more information). These workpieces automatically acquire the same name as that of the part including an additional prefix the meaning of which is entered in the field described herein. |

| ▪ | Composite Material - field used to indicate a desired prefix for the name for the part workpiece glued from other parts. Woodwork for Inventor part workpieces can be designed from several parts consisting of workpieces (click here for more information). These workpieces automatically acquire the same name as that of the material assigned to it including an additional prefix the meaning of which is entered in the field described herein. |

| ▪ | Woodwork for Inventor has an option of writing different data created during BOM generation in parts from the model of which this data was calculated. Examples would include part length or part width. On another hand, you can indicate to the system that the data written in the part as Custom iProperty can be included in a BOM. This is performed by providing a data field linking map in the Specify Mapping area. |

If:

| ▪ | you want to transfer data from the BOM to the part, first, in the Woodwork for Inventor BOM property column (seen as number 5 in the figure) you have to enter a BOM keyword the value of which you want to export to the Customer iProperty field of the part. Once you enter the keyword, the data flow direction automatically changes in this field (seen as number 4 in the figure). In the Custom iProperty column (seen as number 3 in the figure), you must enter the name selected by the user and best describing the exported parameter. When Woodwork for Inventor BOM generator is used, the aforesaid Custom iProperty fields are automatically created for the part and the appropriate values are assigned to them. |

| ▪ | If you want to use Custom iProperty parameter value in the BOM being generated, you have to register Custom iProperty as Woodwork for Inventor data. This is done by entering Custom iProperty name in the column number 3. A keyword will be automatically created in the Woodwork for Inventor BOM property field (seen as number 5). Once this keyword is entered in the desired location of the BOM template, Custom iProperty value will be exported to the BOM. Data flow direction will remain unchanged, i.e. from the part to the BOM. |

The figure provided shows how the calculated part size is returned to the part Custom iProperty fields. In the last row, the datum from the ERP system may be included in the BOM using the keyword on the right.

Write BOM data to mapped iProperties on save - writing Woodwork for Inventor data to Custom iProperties at the time of saving the file.

| 6. | on save - writing Woodwork for Inventor data to Custom iProperties at the time of saving the file. |

| 7. | on BOM close - writing Woodwork for Inventor data to Custom iProperties at the time of closing the BOM generator. |

| 8. | on running "Auto Plot" command - when Auto Plot command is activated.

|

| 9. | on runing "CNC Output" command - when CNC output is activated.

|

| 10. | Write Header data to Assembly document - sets the option using which the data contained in the BOM are described as the BOM header so that they can be written to the assembly component. Later, this allows using the data in Woodwork for Inventor drawing templates by entering the appropriate keywords in the desired locations. AutoPlot command interprets these keywords and automatically exports the data to generated drawings. |

| 11. | Use Vault Functionality - allows enabling/disabling Woodwork for Inventor functionality used to integrate data in Autodesk Vault Professional. Woodwork for Inventor recognizes the project type and automatically enables the functionality used to automatically generate BOMs of an element containing Woodwork for Inventor data. When working with Autodesk Vault Basic, this functionality is not necessary, since integration at the file metadata level is sufficient. Integration at item data level causes problems, if this Autodesk Vault configuration is selected; therefore, there is an option that allows disabling this functionality. |

|

![]()