Opening a CAM environment

To create CAM technological operations for a part, you have to enter the CAM environment of the Woodwork for Inventor add-on. There are two ways that the user can do this:

1.Entering the Woodwork for Inventor CAM environment from the part design environment. In this case, you have to select the "Environments" tab in the top menu bar. In the appearing toolbar, click on the icon as shown below.

WoodworkCAM ![]()

The appearance of the toolbar containing tools for creating CAM technological operations and a changed content of the side browser with the "WCAM pane" title on top are an indication that you have entered a CAM technology design environment.

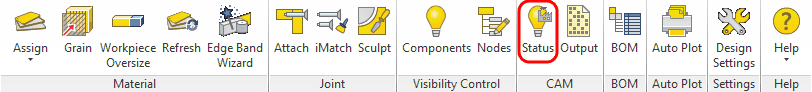

2. Entering the Woodwork for Inventor CAM environment from the assembly design environment. This is performed from the Woodwork Design toolbar using the CAM status highlight function.

After clicking this button, the open assembly will be analyzed and the status of each part will be represented.

3. The following symbols are used to represent the CAM status:

☐- the red empty rectangle means that the part has never been opened in the CAM environment and no CAM technological operations have been created for this part.

☑- the green rectangle with a check mark means that the part contain CAM technological operations.

☒ - the green rectangle with an X mark means that the part has been opened in the CAM environment but the user closed it without creating any processing operation. This means that the user reviewed the part but felt no need to create technological operations for this part. These usually include insertable shelves that can be inserted, cardboard back panels, etc.

If you move the cursor over this symbol, the part will be highlighted and if you press the left (LMB) mouse button, this part will be opened in the Woodwork CAM environment.

Workflow stages

To create CAM technology, you have to follow a certain sequence of steps as specified below:

1.Create a Job for a given part. While creating the Job, select the machine for which CAM technology will be created. The part may have several jobs. This may be the case where the processing of the part is performed using several machines or where there is a need to prepare the processing operations of the part for several alternative routes.

2.Set the base point or, in other words, create Clamping for the part. The part may have several clampings. This depends on the shape of the part to be processed and the technological capabilities of the machine.

3.Create processing operations. Currently, Woodwork CAM supports the creation of the following operations:

a. ![]() Drill operations.

Drill operations.

b. ![]() Mill operations.

Mill operations.

c. ![]() Pocket operations.

Pocket operations.

d. ![]() Groove operations.

Groove operations.

e. ![]() Cut operations.

Cut operations.

4.Generate CNC programs.

Before proceeding with a detailed explanation as to how the user may create and manage the data of the above stages, let us look at the next section which explains how to set the configuration of the machine for which technology is being created and how this impacts the creation of CAM technology itself.