Woodwork4Inventor automates size calculation for blanks which haves rectangular parallelepiped shape. In furniture construction, parts which haves bended shape form occur.

Bended doors

Such parts are produced from hardboard sheets. They are glued on a specific punch. We need to specify the sheet length and width which are necessary for producing a bended part. We can do it in two ways:

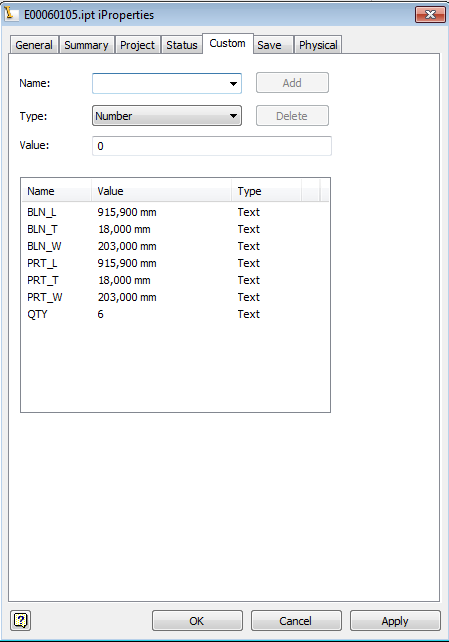

The first way we can be used for manually recorded sizes parts (see table Part types for the exploration of concept Size calculation topic). It is enough in iProperties Custom parameters TAB to create parameters:

•PRT_L - part length

•PRT_W - part width

•PRT_T- part thickness

•BLN_L - blank length

•BLN_W- blank width

•BLN_T - blank thickness

You can also specify the Qty parameter which informs Woodwork BOM that the quantity of this component in the product becomes equal to the own quantity multiplied by Qty, and the size of PRT T and BLN T is divided by Qty.

The second way to specify the blank and part size is to measure the geometry of the part. Autodesk Inventor Edges and Sketch lines can be specified as measured elements. These measurements are associative. It means that when you generate BOM or calculate the part size, parameter part sizes will be recalculated according to the changed 3D model of part.

You can perform such measurement on persistent measurement part types (see table Part types for the exploration of concept Size calculation topic). For permanent measurements you need to open the part stand alone and apply Furniture Design->Permanent Measures command

Here you are asked to point out a variable and to specify any part edge/s or sketch line/s which length sum will be counted as specified parameter value. Check box allows to break associativity and to specify a new set of geometric elements.