Part and Blank size calculations is one of the main task when the information for furniture manufacturing is prepared. Some confusion in calculating it arises from the fact that a furniture part in Woodwork4Inventor is considered to be glued assembly. Such assembly consists frof the main material blank and coverings. In our case we treat edge bands as coverings. Sometimes in the furniture design process it is not clear what your Autodesk Inventor part model means - Part or Blank? Woodwork4Inventor allows the user to choose freely what he prefer to model in Autodesk Inventor - Part or Blank and to get a right Bill Of Material for manufacturing.

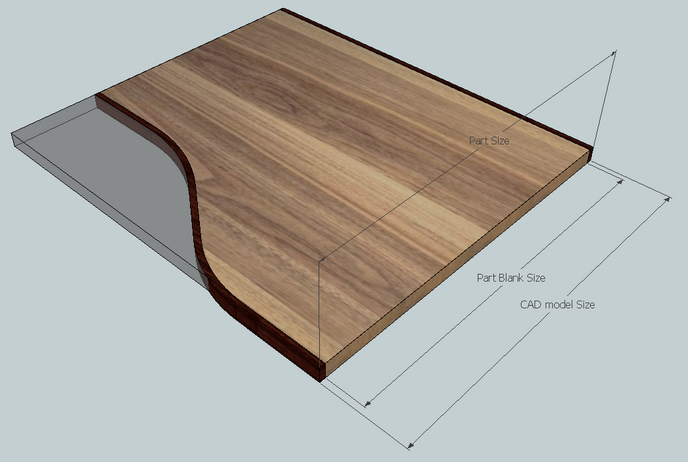

Woodwork4Inventor always generates two size sets defining the furniture part:

•Part Size (Size with Edge banding)

•Blank Size (Size which should be cut from a purchased board)

We have two size calculation situations after a 3D furniture part model is created and material and edge banding is applied:

•Edge band enlarges Part Size and Blank size is the same as CAD model range box

For Example:

Blank Size.Width=CAD Model.Width

Part Size.Width=CAD Model.Width+Edge Band.Thickness*2

•Edge band reduces Part Blank Size and Part size is the same as CAD Model range box

For Example:

Blank Size.Width=CAD Model.Width-Edge Band.Thickness*2

Part Size.Width=CAD Model.Width

Edge Band reduces Part Blank Size

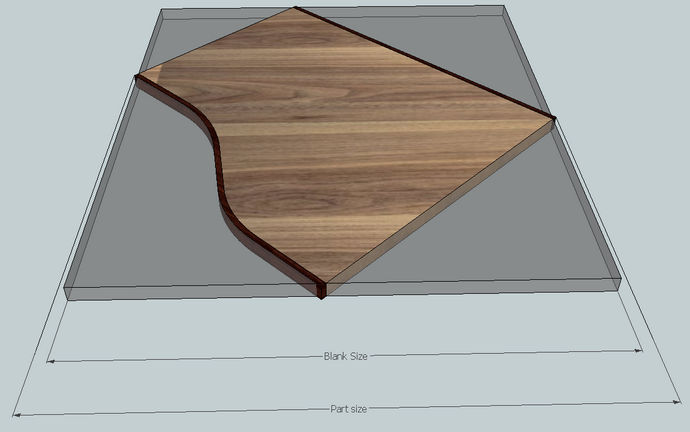

Also Woodwork4Inventor allows to rotate Texture direction of the part and sizes of the Blank and the Part will be calculated taking into account the texture direction.

Blank and Part Size calculation according to texture direction rotation

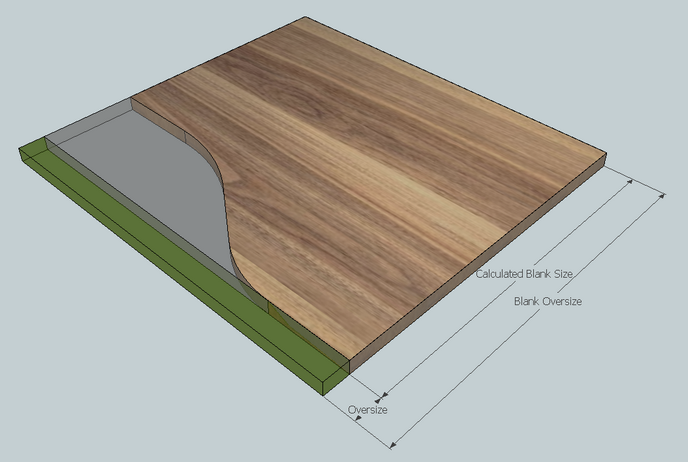

In situations when contour milling operations are applied, the Part Blank should have be greater than it is automatically calculated on certain specified overlap. Woodwork4Inventor allows to do it.

Oversize influence to Blank Size calculations

Every time when you need Part or Blank Size Woodwork4Inventor calculates the Parts Range box. Orientation of the box depends on the texture direction. The system analyzes Autodesk Inventor model and assumes that the maximum area face is the face where the texture direction lies. By default the texture direction is aligned to the longest straight edge, If face does not have such an edge, the software calculates arbitrary coordinate system on a maximum area face and aligns the material texture direction along the X axis direction. This texture direction and biggest face normal direction describesthe part size range box calculation orientation in space. When you change the texture direction, you change orientation of the range box. You can find out how to manipulate the texture direction in the topic Sizes calculation.