Item type =

|

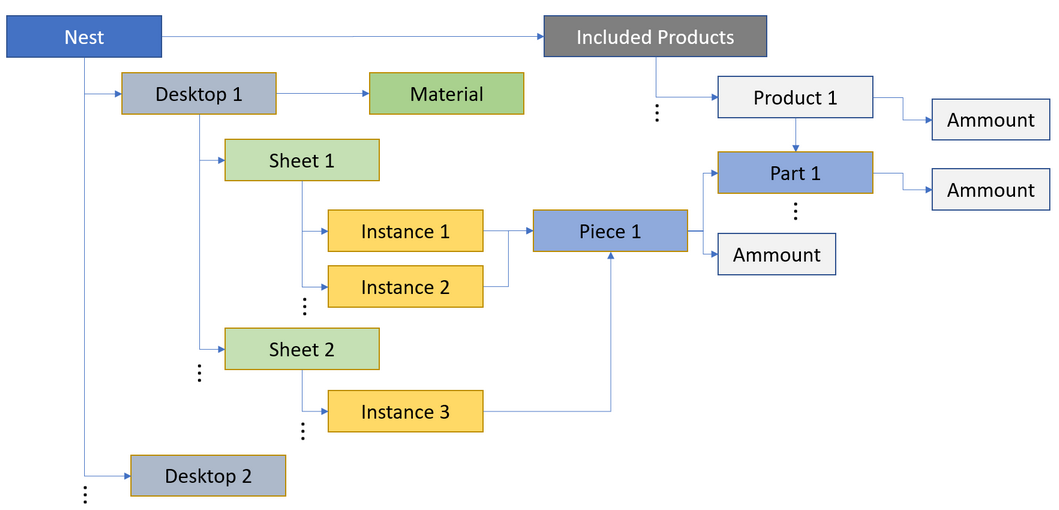

Nest

|

|

{Item.

|

|

|

|

Code}

|

Designed shape nesting code. Its value is taken from the Code field, which is available in the Properties tab of the side browser. This value can be edited by the user..

|

|

Name}

|

Designed shape nesting code. Its value is taken from the Name field, which is available in the Properties tab of the side browser. This value can be edited by the user.

|

|

FileDrive}

|

Outputs the hard drive address where the designed shape nesting file lies.

|

|

FilePath}

|

Outputs the path where the designed shape nesting file lies.

|

|

FileName}

|

Outputs the name of the designed shape nesting file.

|

|

FileNameWithoutExtension}

|

Outputs the name of the designed shape nesting file without extension.

|

|

FullFileName}

|

Outputs the full name of the designed shape nesting file and the path.

|

|

DesktopCount}

|

Number of raw material worktops in the designed shape nesting.

|

Item type =

|

Desktop

|

|

{Item.

|

|

|

|

Index}

|

Outputs raw material worktop index provided by shape nesting editor.

|

|

Material.<Material Properties>}

|

Outputs raw material properties.

The main properties are listed below:

The remaining properties and their description are available in Keyword Auto Complete.

|

|

PieceCount}

|

Outputs the number of pieces in the given worktop.

|

|

PieceInstanceCount}

|

Outputs the number of piece instances in the given worktop.

|

|

SheetCount}

|

Outputs the number of raw material sheets in the given worktop.

|

|

InfillEficiency}

|

Overall efficiency of filling raw material sheets.

|

|

Machine.<Properties>}

|

Outputs the properties of CNC machine which processes raw material sheets of the given worktop.

Available properties:

|

Item type=

|

Sheet

|

|

{Item.

|

|

|

|

Index}

|

Raw material sequence number on the worktop.

|

|

Name}

|

Name of the raw material sheet.

|

|

TopCover.<Material Properties>}

|

Properties of the top cover material. Relevant for multilayer boards, when outputting information about the side of the board facing up during shape nesting.

|

|

BottomCover.<Material Properties>}

|

Properties of the bottom cover material of the board. Relevant for multilayer boards, when outputting information about the side of the board facing down during shape nesting.

|

|

Nesting.<Nesting properties>}

|

Gives access to all properties of the given shape nesting.

|

|

Desktop.<Desktop Properties>}

|

Gives access to all properties of raw material worktop.

|

|

PieceCount}

|

Outputs the number of pieces in the given sheet.

|

|

PieceInstanceCount}

|

Outputs the number of piece instances in the given sheet.

|

|

InfillEficiency}

|

Efficiency of filling the given raw material sheet.

|

|

Length}

|

Sheet length.

|

|

Width}

|

Sheet width.

|

|

Thickness}

|

Sheet thickness.

|

|

Margin}

|

Outputs the size of sheet margins.

|

|

SheetImage(<height>)}

|

Outputs the image of the given sheet for printing as an MS Excel file according to printing settings defined for the sheet.

|

|

CNCprogram.

|

Outputs CNC program properties.

FileName}

|

Name of the CNC program file.

|

FileNameWithoutExtension}

|

Outputs the name of the CNC program file without extension.

|

FileDrive}

|

Outputs the hard drive address where the CNC program file lies.

|

FilePath}

|

Outputs the path to the CNC program.

|

FullFileName}

|

Outputs the full name of the CNC program file and the path.

|

Machine.<Machine Properties>}

|

Outputs the properties of the CNC machine processing this raw material sheet.

|

|

Item type =

|

Instance

|

|

{Item.

|

|

|

|

Piece.

|

Access to the properties of piece instance..

|

|

Nesting.<NestingProperties>}

|

Gives access to all properties of the given shape nesting.

|

|

Desktop.<Desktop Properties>}

|

Gives access to all properties of raw material worktop where the given instance lies.

|

|

Sheet.<Sheet Properties>}

|

Gives access to all properties of raw material sheet where the given instance lies.

|

|

CountInSheet}

|

Outputs the number of given instances on the sheet where it lies.

|

|

CountInDesktop}

|

Outputs the number of given instances in the whole raw material worktop.

|

|

Pozition.<Coordinate>}

|

Position of the base point of given piece instance in CAM technology with respect to the base point of the raw material sheet.

Coordinate: X or Y

|

|

AngleDeg}

|

Rotation angle (in degrees) of given piece instance on raw material sheet in CAM technology.

|

|

AngleRad)

|

Rotation angle (in radians) of given piece instance on raw material sheet in CAM technology.

|

|

InstanceImage(<Height>}

|

Outputs the image of the given piece in the keyword cell (at given height). Uses image printing settings as a MS Excel file.

|

|

InstanceImageInSheet(<Height>)}

|

Outputs the whole raw material nesting scheme highlighting the given piece on this sheet in the keyword cell (at given height).

Uses image printing settings as an MS Excel file.

|