The CNC program output command can be accessed:

| 1. | From the "Woodwork CAM" part environment: Woodwork CAM -> Output |

| 2. | From the "Woodwork Design" assembly environment: Woodwork design -> Output |

There is a clear difference between outputting CNC data for one part and for the entire assembly: in the former case, a CNC program is generated for a single part, and in the latter case it is generated for all the parts existing in the assembly. Moreover, if we are in the part environment, the program is generated only for an active node. For example, if the part has two clampings and one of them is active at a given moment, the program will then be generated only for this active clamping. In order for the system to generate CNC programs for all clampings, you need to activate the Job or the entire technology.

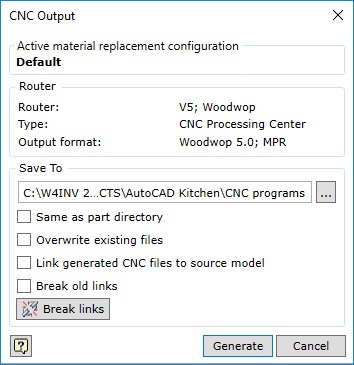

Active material replacement configuration |

Shows the active material replacement configuration. In some post processors, information about the part (including the material) is transferred to the generated CNC program in the form of a comment.

|

Router |

Provides information about the machine which services the given Job and which is included in the CNC machine’s configuration.

|

Save To |

Indicates the location for storing CNC programs. If the option "Save as part directory" is on, the selection of the storage location for CNC programs will not be not applicable.

|

Same as part directory |

Saves the CNC program in the same Directory where the part itself is located. |

Overwrite existing files |

If this option is on, the existing files will be overwritten. If this option is off, the old files will be preserved, and a new file will be created with an order number assigned to it.

|

Link Generated CNC files to source model

|

The option turns on automatic creation of Link for the source model to the CNC program file. |

Break old Links

|

The option turns on automatic deletion of previously created links to CNC programs before creating new links. |

Break links |

Command, which deletes all links to CNC programs. |

Once the generation of CNC files is completed and if one CNC program file has been generated, it is recommended opening it in the editor of such programs as, for example, Woodwop or IMAWOP environment. If multiple files have been generated to the indicated directory, it is advisable to open this directory in Windows Explorer.

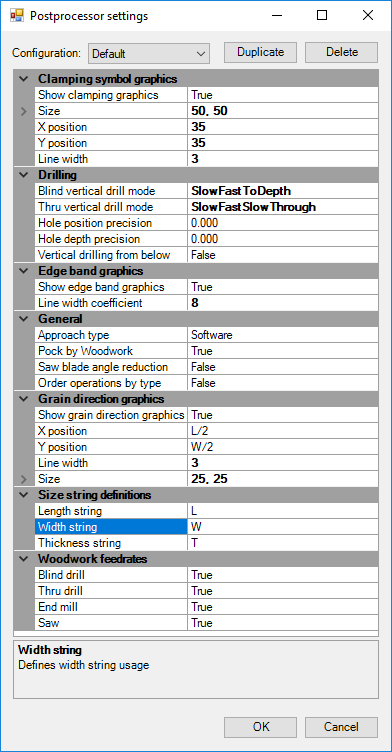

Configuration of Post Processor output parameters

The Woodwork for Inventor CAM module saves and stores in entire CAM technology in the part file. However, this information must be converted into the language understandable by a given machine. This task is performed by the Post Processor program. We specify this program when configuring a CNC machine. As already mentioned above, when setting a Job for the part, at the same time the machine which will be used for performing the job is selected. Each Post Processor may have additional individual settings which control the nuances of the program outputted to a specific CNC machine. The Post Processor is designed like an executable file, thus it can be run like any executable file of the Windows operating system. If the Post Processor is started separately, it runs in a self-configuration mode. The program opens a window containing all adjustable options of the given Post Processor.

Woodwop Post-Processor configuration window

Once Post-Processor configuration is enabled, a window opens that is used to adjust various CNC code output options.

| ▪ | Configuration allows choosing a configuration for which Post-Processor operational parameters are defined. |

| ▪ | Duplicate allows copying the current configuration. |

| ▪ | Delete is used to delete the current configuration. Default configuration cannot be deleted. |

After changing these options, the user can obtain different results which are generated in the CNC program. The options list is unique for each Post Processor and very much depends on what the output information is generated for.