To open the Sizing by Saw command:

Woodwork CAM -> Sizing->By Saw ![]()

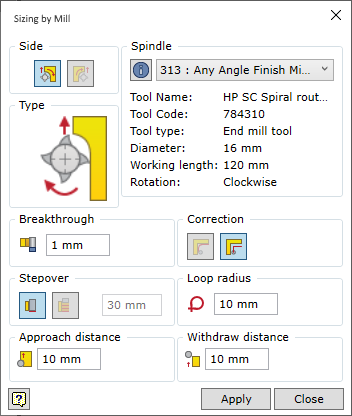

In order for the command to run smoothly, the user has to follow a certain order of specifying the data. The description of the command control in the sequence to be followed when working with milling command window is provided below.

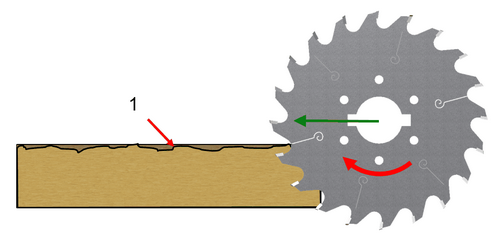

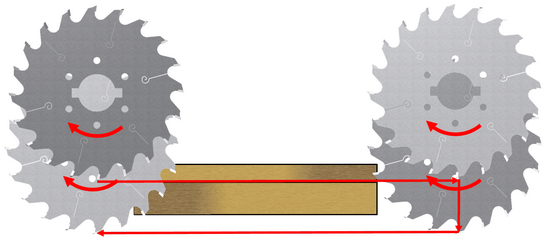

Two spindles have to be specified for a sizing operation: Spindle for Front and Back Cut and Spindle for Left and Right Cut.

|

| 1. | Update properties only for selected operation - overwrite changed properties only for the current operation. |

| 2. | Update properties in all operations in current technology - overwrite changed properties for all operations in the current technology. |

| 3. | Update properties for database - overwrite changed properties in the database. |

The command remembers the last selected spindles and their loaded tools. If during the next run of the command the same spindle with the tool is used, the user does not need to select it again.

The following options are available for the scoring pass:

|

Setting the saw withdrawal distance from the cut surface. |