System settings allow the user to adjust the operation settings of the Woodwork for Inventor add-on

To open the command, go to:

Woodwork Design –> Help –> Settings ![]()

The command has four tabs used to adjust the following operational aspects of Woodwork for Inventor:

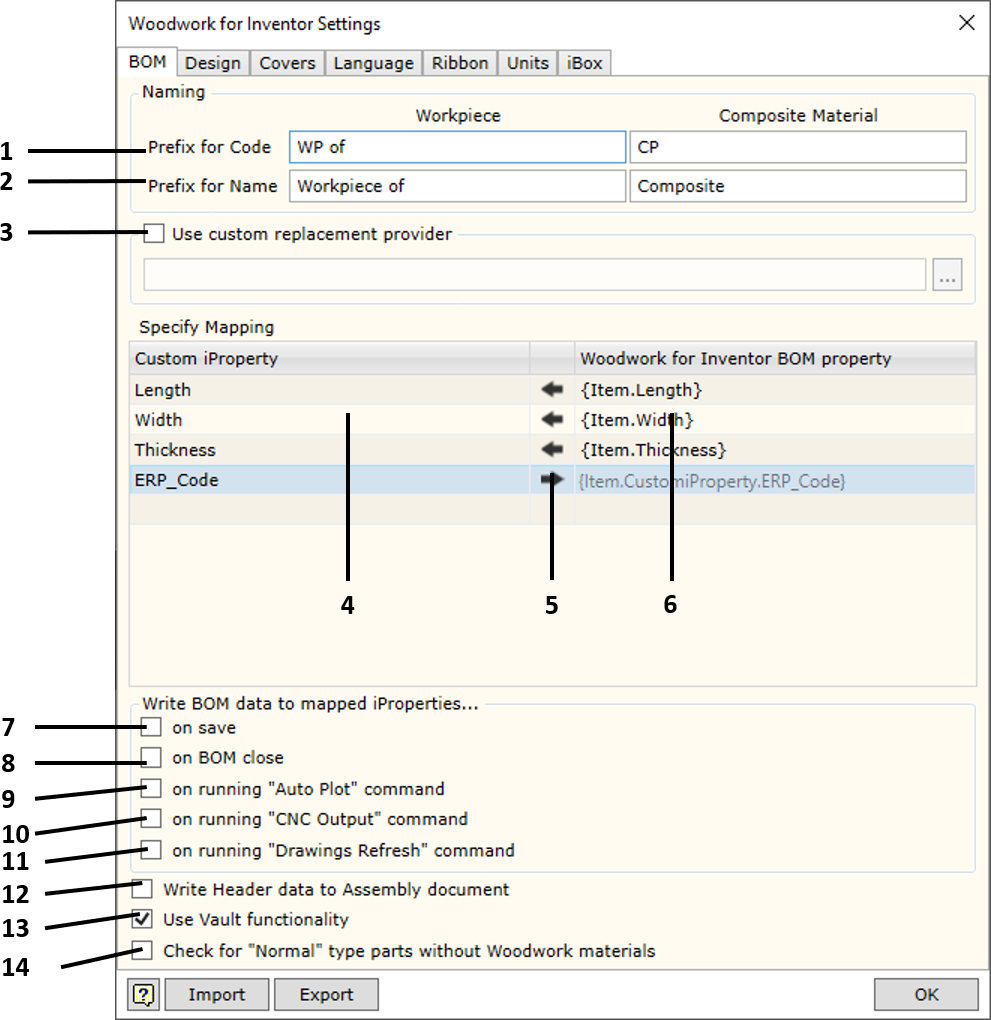

1. Prefix for Code - sets prefix for the code.

2. Prefix for Name - sets prefix for the name.

3. Enables/disables the application developed by the user for servicing material replacement procedure. The users now have the opportunity to develop their own application for retrieval of material information and to use it instead of the standard Woodwork for Inventor procedure, which uses MS Excel table as a source of information in material replacement procedure. File specification field is intended for indicating a .dll file, which implements the data retrieval method designed by the user.

If:

The figure provided shows how the calculated part size is returned to the part Custom iProperty fields. In the last row, the datum from the ERP system may be included in the BOM using the keyword on the right.

Write BOM data to mapped iProperties on save - writing Woodwork for Inventor data to Custom iProperties at the time of saving the file.

7. on save - writing Woodwork for Inventor data to Custom iProperties at the time of saving the file.

8. on BOM close - writing Woodwork for Inventor data to Custom iProperties at the time of closing the BOM generator.

9. on running "Auto Plot" command - when Auto Plot command is activated. 10. on runing "CNC Output" command - when CNC output is activated.

11. on runing "Drawing Refresh" command - while running the Drawing Refresh command. 12. Write Header data to Assembly document - sets the option using which the data contained in the BOM are described as the BOM header so that they can be written to the assembly component. Later, this allows using the data in Woodwork for Inventor drawing templates by entering the appropriate keywords in the desired locations. AutoPlot command interprets these keywords and automatically exports the data to generated drawings.

13. Use Vault Functionality - allows enabling/disabling Woodwork for Inventor functionality used to integrate data in Autodesk Vault Professional. Woodwork for Inventor recognizes the project type and automatically enables the functionality used to automatically generate BOMs of an element containing Woodwork for Inventor data. When working with Autodesk Vault Basic, this functionality is not necessary, since integration at the file metadata level is sufficient. Integration at item data level causes problems, if this Autodesk Vault configuration is selected; therefore, there is an option that allows disabling this functionality.

14. Check for "Normal" type parts without Woodwork for Inventor materials - enables/disables verification whether the constructed assembly does not have any parts with no Woodwork for Inventor material assigned to them. Such parts will not be included in Woodwork for Inventor specification. If the option is enabled, BOM generator gives a message with a list of such parts.

|

|

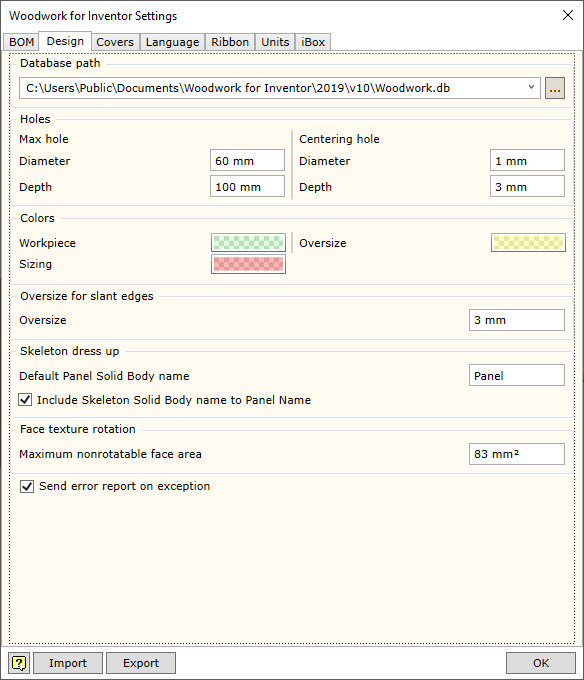

Materials Database path - specifies the location in which the Woodwork for Inventor material database is placed. Its default location is: C:\Users\Public\Documents\Woodwork for Inventor\2020\v10\Materials.sdf

If several designers work for the same organization, it is recommended to keep a centralized database. If this is the case, the database will be stored on the server and will have the assigned path.

|

|||||||||||||||||||||||||||||||||||||||||

|

Woodwork for Inventor

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

In this section you may select the language for Woodwork for Inventor. To enable the selected language, you have to close and re-start the Autodesk Inventor program.

|

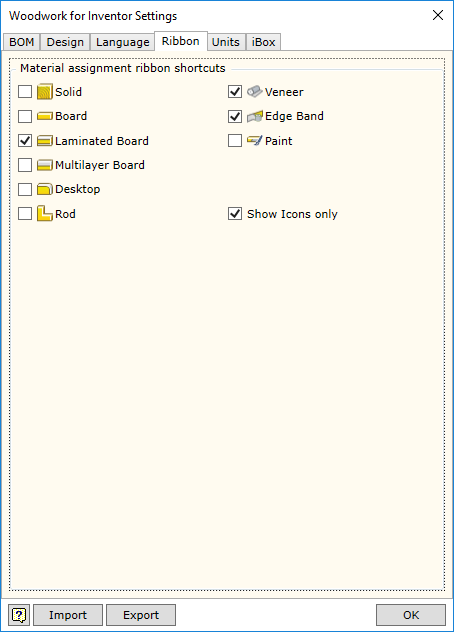

Allows enabling/disabling additional commands in Woodwork for Inventor toolbar, which facilitate the assignment of materials.

Show Icons Only - disables output of commands explaining items in the toolbar.

|

In this window you will see a unit settings dialog presented in the form of a hierarchical tree structure.

Units are displayed in the form of a hierarchical tree. Unit settings selected in the higher level will apply to lower branches as well if not otherwise specified in the lower branch. The hierarchical tree is divided into the following levels:

The first level:

The second level describes the following:

In the third level, you may adjust unit display for specific types of materials:

In the fourth level, you may describe the following for each material type:

The user may save the settings to the external file and transfer them to the system. The installation of the Woodwork for Inventor add-on offers the following two configurations:

|

|