Parts can be cut from a single raw material sheet only with CNC Nesting Router machines. With these machines, the search procedure of clamping options is slightly different. Here, such factors as the support of a part against base supports are irrelevant, so finding the base panel is also irrelevant.

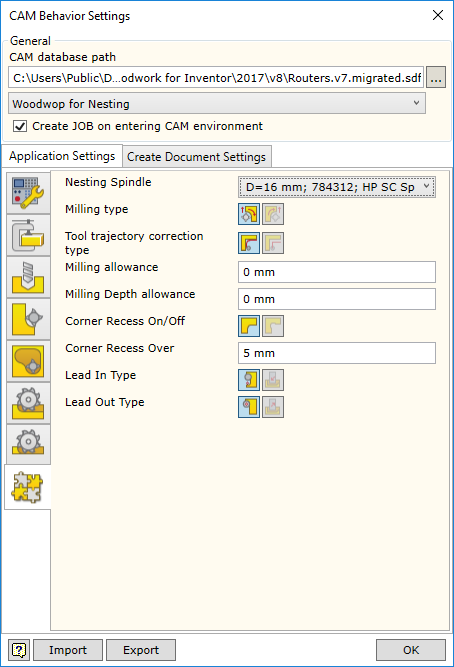

These settings are accessed from the settings tab for the cutting of parts from a single sheet.

Mill Spindle |

Selects a spindle used to cut parts from a single sheet. Below, parameters of the operation created by CAM solver for this spindle are defined.

|

Miling type |

Setting the side, from which the loop is followed, and the milling type. To read more, click here.

|

Tool Trajectory correction type |

Setting the correction type. To read more, click here. Keep in mind that in cases, where the calculation method of machine trajectory is given as the original contour, it is impossible to ask the program to generate repositioned contour.

|

Milling allowance |

Milling allowance.

|

Milling depth |

Milling depth allowance.

|

Corner Recess On/Of |

Additional corner recess. To read more, click here.

|

Corner Recess Over |

Setting the size of the corner recess.

|

Lead In Type |

Setting the trajectory of lead in: cutting into the milling contour.

|

Lead Out Type |

Setting the trajectory of lead out: pulling away from the milling contour cut. |