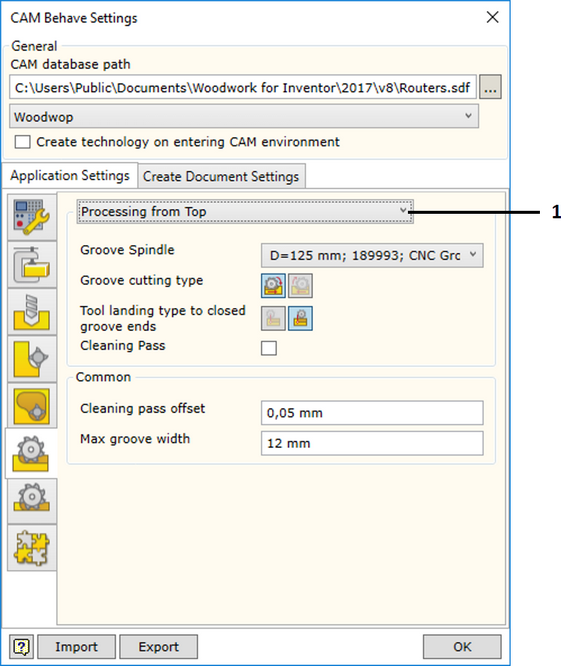

Grooving operation has parameters controlling various aspects of the technology being created, such as: cutting type, saw landing type, etc. The technology is created for all spindles included in the configuration of the machine, thus grooving operation settings may differ for the processing using top oriented or free oriented spindle. Therefore, the software allows the user to adjust these aspects separately for top oriented and free oriented spindle.

These settings are accessed from the grooving operation settings tab.

1. Orientation Selector |

The selector allows choosing spindle operations for which the settings specified below will be applied. The following options are available:

Important. Unlike with analogous descriptions of other tool types, in cases, where top oriented spindle is indicated, it is implied that the saw cuts the upper plane of the part. Orientation vector describing the degree of freedom of the position of spindle and saw will be restricted by a direction corresponding to the top plane. While with mills and drills, a direction that is normal in terms of the top plane of the part is considered. For more information on the restrictions of spindle orientation, click here. Different spindles and different operation parameters can be specified for individual orientations.

|

||||

Groove Spindle |

a machine spindle is selected for the spindle orientation selected in the selector. Below, parameters of the operation created by CAM solver for this spindle are defined.

|

||||

Groove cutting type |

Setting the cutting type. To read more, click here.

|

||||

Tool landing type to closed groove ends |

Setting saw landing and lifting type with closed groove ends. To read more, click here.

|

||||

Cleaning Pass |

Turns on or off the cleaning pass of the saw. To read more, click here.

|

||||

Cleaning pass offset |

Setting the distance from the cut groove surface, at which the saw has to be lifted during the cleaning pass. This parameter is also used in the Woodwork for Inventor CAM module, when the operation is created as usual.

|

||||

Max groove with |

Setting the width of a part model, for which, when recognized, the groove has to be processed using a saw, and the width, from which it will be deemed that it is better to process the groove using an end mill. The parameter is also used in the Woodwork for Inventor CAM module, when groove geometry is automatically selected from the part model for the operation. |