When preparing information about a product, various specification forms may be required. Woodwork for Inventor offers several specification and table types. Interpretation of Woodwork for Inventor model data differs depending on the selected type. This also affects the form of data presentation. Different specification types can be used to meet all the needs of the users for presenting the information from various points of view.

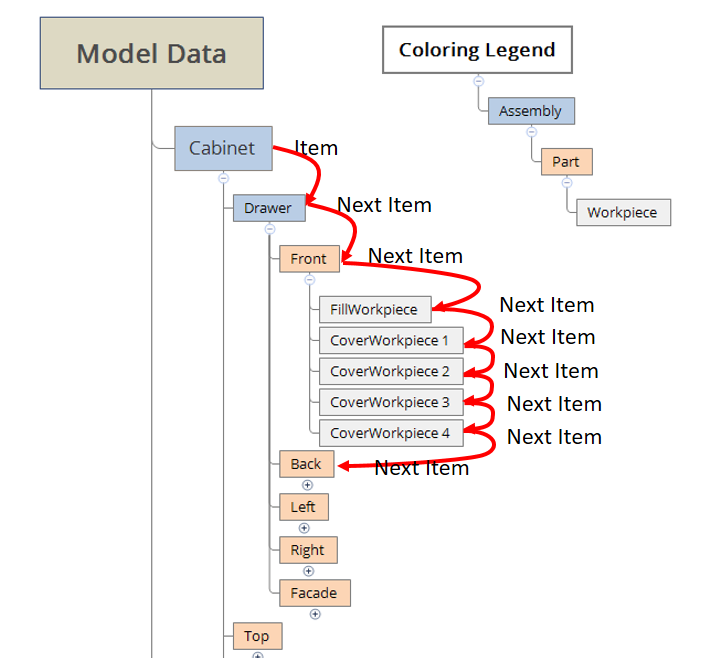

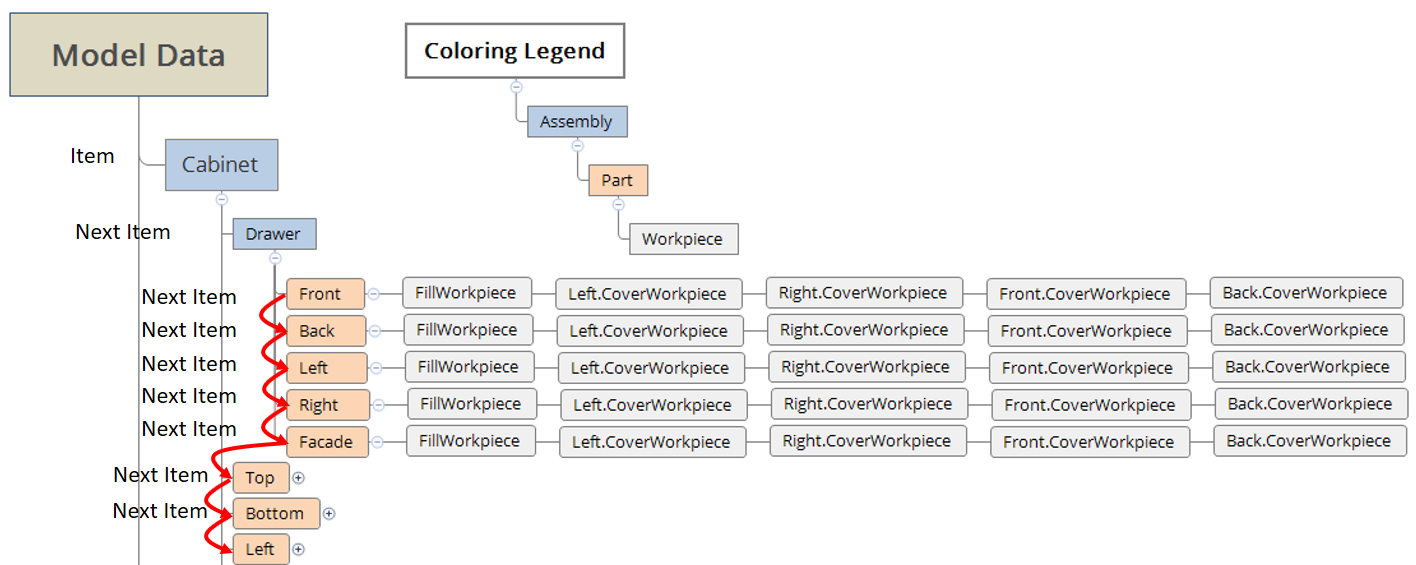

Diagram showing interconnection of specifications generated by Woodwork for Inventor and tables used in these specifications

The start point of different specifications and tables is entered using keywords in the template. The diagram presents keywords that mark specification and table types. For more information about the structure to be followed in a template, click here.

Specifications generated by Woodwork for Inventor can be classified into two groups:

| ▪ | Components BOM – specification class that includes different types of information about individual components in the model data. |

| ▪ | Materials Summary BOM – specification class that presents information about materials and their quantities necessary to manufacture the product displayed in the model data. |

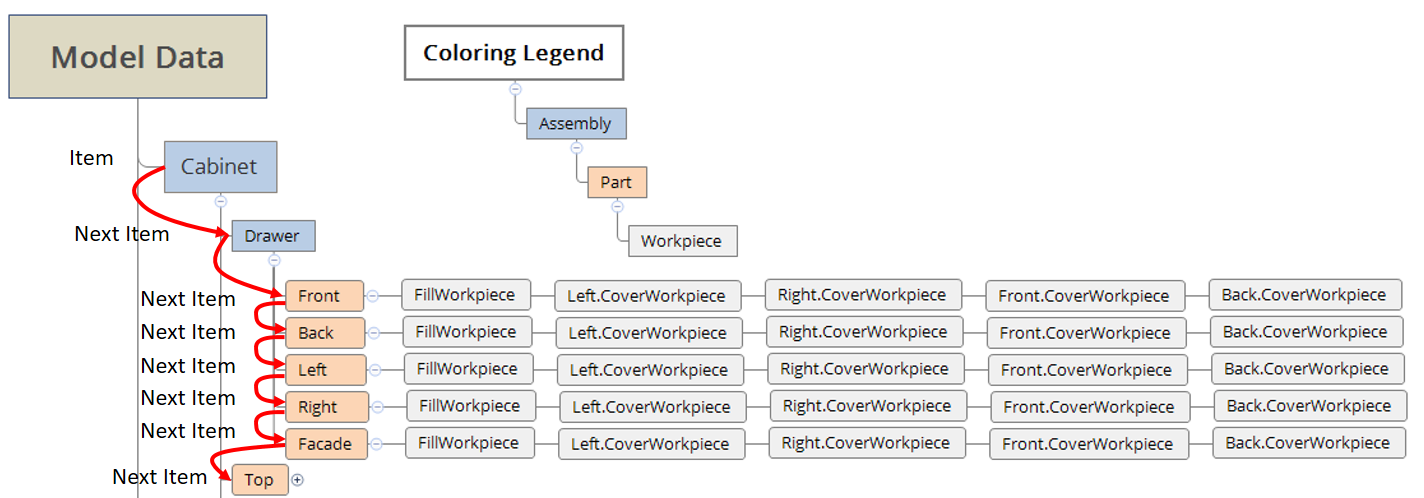

The keyword starts a specification from the Components BOM class. Depending on the table opened in the specification, the tables are displayed as a fixed tree structure in the model data. Only one table of the selected type can be included in such specification. The following table types are used in this type of specification:

|

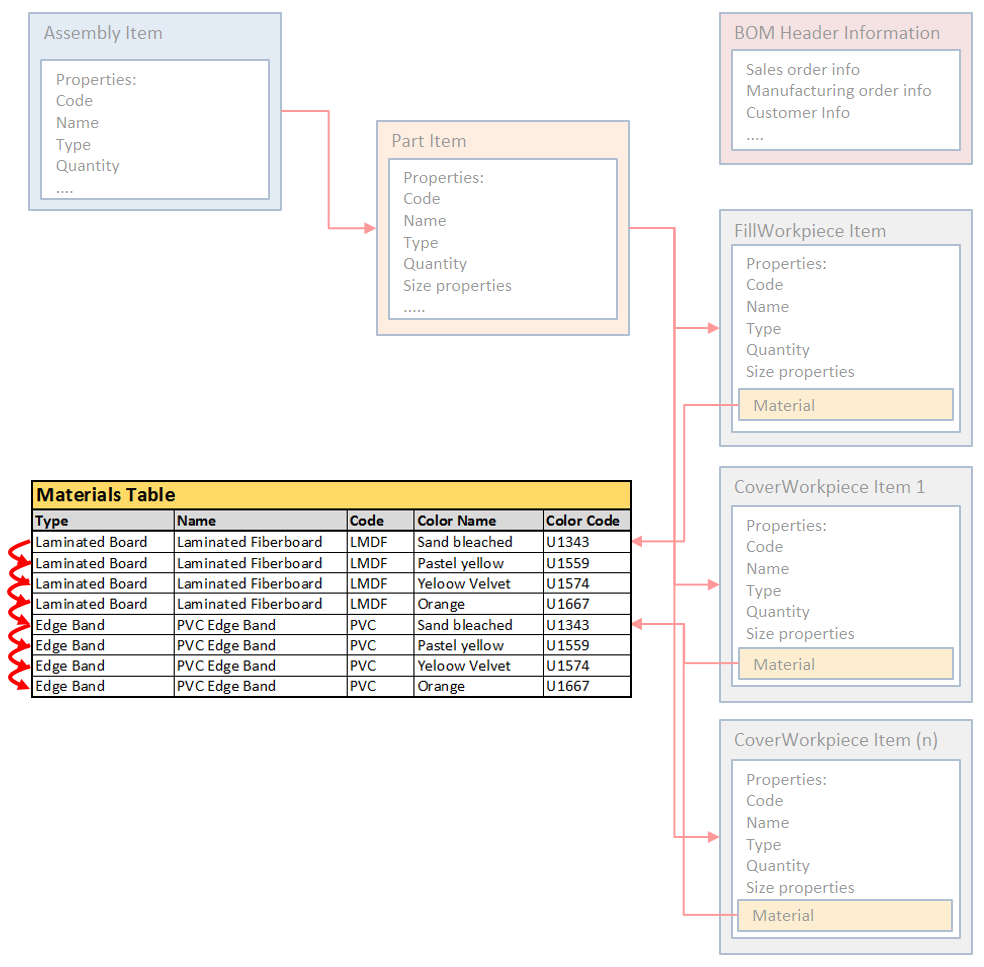

The keyword starts a specification from the Components BOM class. Specifications from this class always scan the model data by iterating through part nodes ignoring assembly nodes. Several tables can be composed in a single specification of this type. Each table includes Woodwork for Inventor parts made of the material type specified for the table. For example, all parts made of board will be presented in Table.Start.Board table. Parts made of other materials will be presented in the appropriate tables. This allows sorting the parts in an orderly fashion by the type of material of which they are made. To access workpiece data in this type of table, a composite keyword that allows accessing the workpiece data has to be entered in one of the columns. For example, to find out the workpiece length, you will have to enter the keyword {Item.FillWorkpiece.Length}. The number of cover workpieces varies, thus data of these workpieces is accessed using indexes. The following indexes are used to access cover workpieces:

For example, to open cover color code of the left side of the part, you will have to enter the keyword {Item.CoverWorkpiece.Left.Material.Color.Code}. If no covers with such index could be found in the model data, MS Excel cell is left blank.

|

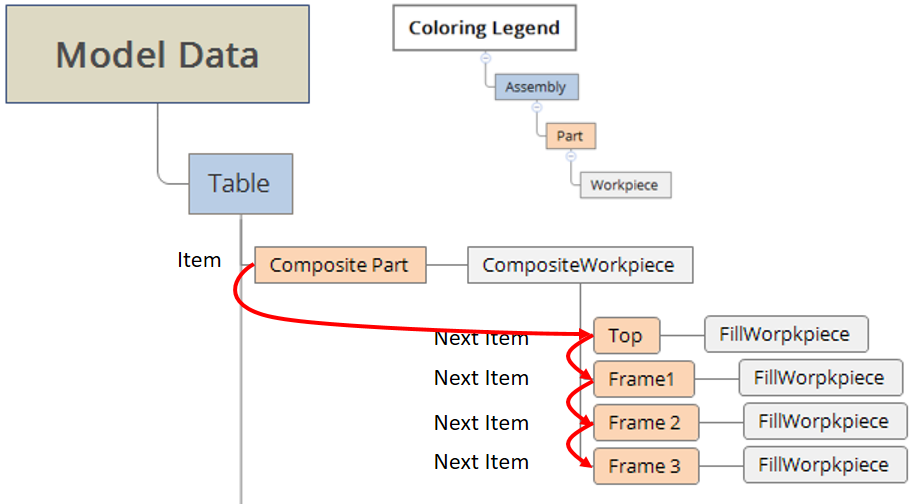

The keyword starts a specification presenting information about materials. In this case, the program iterates through items in the material table. Keywords can be used to access all characteristics of the material, including quantity of each material necessary to produce the product described in the model data. Quantities are presented with the appropriate units of measurement. For more information about Woodwork for Inventor materials, click here.

In this type of specification, several tables can be composed on a single sheet. Each table type presents a summary of the specified type of materials.

|

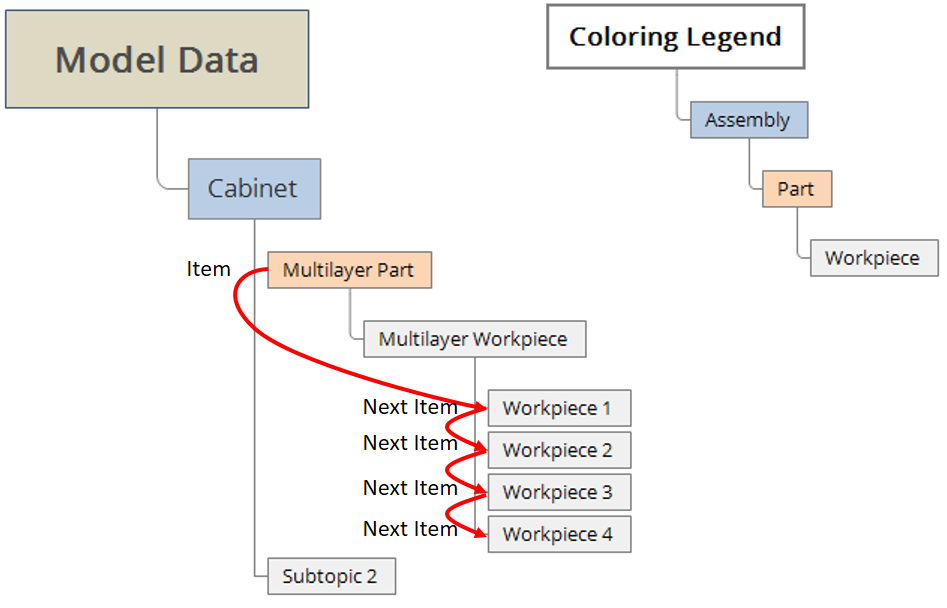

![]() "BOM.MaterialsSummaryByProduct"

"BOM.MaterialsSummaryByProduct"

The keyword starts a specification presenting information about materials in the same manner as in BOM.MaterialSummary specification. However, here, information about materials is broken down by products included in the model data. As described above, previously generated specifications for several Woodwork for Inventor product models can be merged.

BOM.MaterialSummaryByProduct specification is made up of material summary specifications for each product. Where it is inconvenient to create a separate .wbom file for each product and later merge these files to create uniform model data, this can be done by opening an Autodesk Inventor assembly and generating its specification. For example, you have an Autodesk Inventor assembly – a kitchen furniture set, and you want to generate material summary specification for each cabinet. For BOM generator to treat cabinet assemblies as products, the top-level assembly (in this case, the furniture set) has to be marked as a phantom component.

Now, BOM generator will treat each first-level component as a product that requires a separate material summary. Quantities are presented with the appropriate units of measurement. For more information about Woodwork for Inventor materials, click here. |