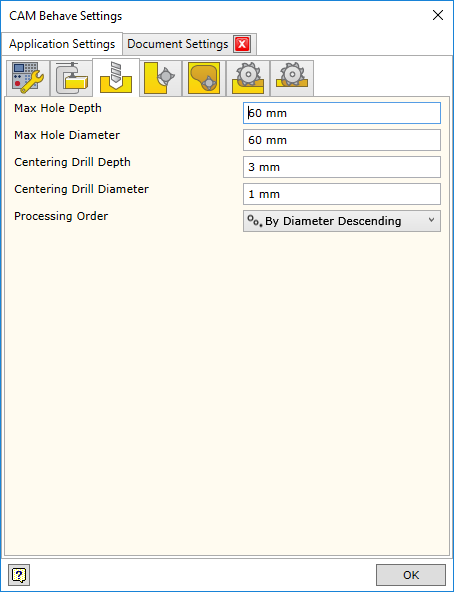

As mentioned above, CAM solver works with B-rep geometry. To reduce ambiguous geometry interpretations, drilling operation settings are defined.

These settings are accessed in the drilling operation settings tab.

Max Hole Depth

|

Setting the maximum depth of a recognized hole in the part, which may be subject to the drilling operation. |

Max Hole Diameter

|

Setting the maximum diameter of a recognized hole in the part, which may be subject to the drilling operation. Otherwise, milling operations can be applied.

|

Centering Drill Depth |

For the purposes of Woodwork for Inventor system modeling, it has been agreed that holes with strictly defined diameter may be treated as centering drill operation. Such hole can be of any depth, but depth defined by this parameter (Centering Drill Depth) will be automatically applied to it.

|

Centering Drill Diameter |

Setting hole diameters, with which it is considered that this is centering drill operation.

|

Processing Order |

Defines the order of priority of drilling operations in the technology. The following options are available:

1. By Diameter Descending - all drilling operations begin with holes with the largest diameter and end with holes with the smallest diameter.

2. By Diameter Ascending - all drilling operations begin with holes with the smallest diameter and end with holes with the largest diameter.

3. By Modeling Order - drilling operations are performed as read from the model.

Important. Woodwork for Inventor CAM module generates codes to intermediary CAM systems, such as Woodwop, IMAwop, etc. rather than the G-code, which directly controls machine tools. Therefore, this defined processing order can be realized differently, since these systems have their own logic for the processing of holes. |