This command changes the component’s grain direction. Changing grain direction directly affects the material workpiece estimate. The command allows the user to change the direction of the fill material and cover material if such is applied to the part. Cover direction can be changed only for a Veneer type material.

To open the command, go to:

Woodwork Design –> Material –> Grain ![]()

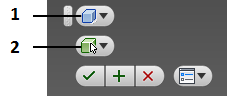

| 1. | Material type selector. Allows you to select a material type for which grain direction need to be adjusted. |

|

|

2. Cover Grain. The command switches to a face selection mode. Using the cursor, you can select a face of the component that has a Woodwork for Inventor cover assigned to it. |

2. Selecting geometry type indicator.

|

Fill grain direction adjustment.

A grain direction indicator will appear on the selected part showing the grain direction of this part. Meanwhile, in the geometry type indicator dialog box, a fill grain direction type selector will appear.

|

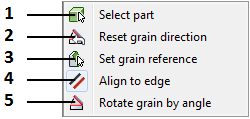

1. Back to the grain adjustment for the next part. 2. Grain direction adjustment using an automatic grain direction search algorithm. 3. Selecting a different reference face of the part based on which grain direction and blank size is calculated. 4. Align to edge. 5. Rotate grain direction at a specified angle. |

By default, align to edge mode is always on.

Cover grain direction adjustment.

After selecting a part face with a cover assigned to it, a grain direction indicator and additional selection options will appear on the face.

|

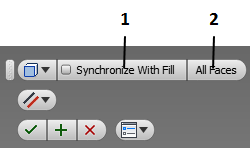

1. The direction synchronization of the selected face with the fill direction. After launching this command, the cover direction of the selected face is synchronized with the fill grain direction. In this situation selecting a different grain direction for this face is impossible until synchronization is cancelled. In this case, the rotation of the grain direction is performed by rotating the fill grain direction.

2. The synchronization of the cover grain with the fill grain is applied to all faces of a given part that have a cover material assigned to them.

|

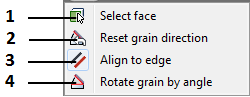

1. Back to grain adjustment for the next face. 2. Grain direction adjustment using an automatic grain direction search algorithm. 3. Align to edge. 4. Rotate grain direction at a specified angle. |