The command opens the material editor.

To open the command, go to:

Woodwork Design -> Material Editor ![]()

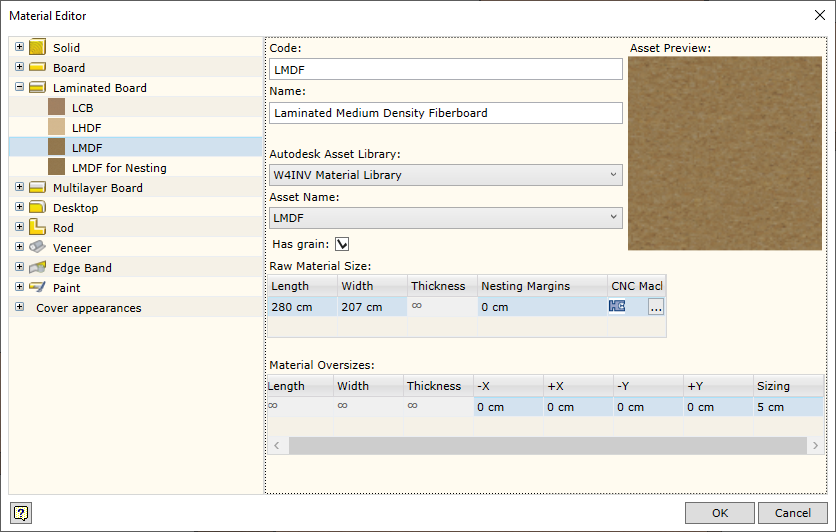

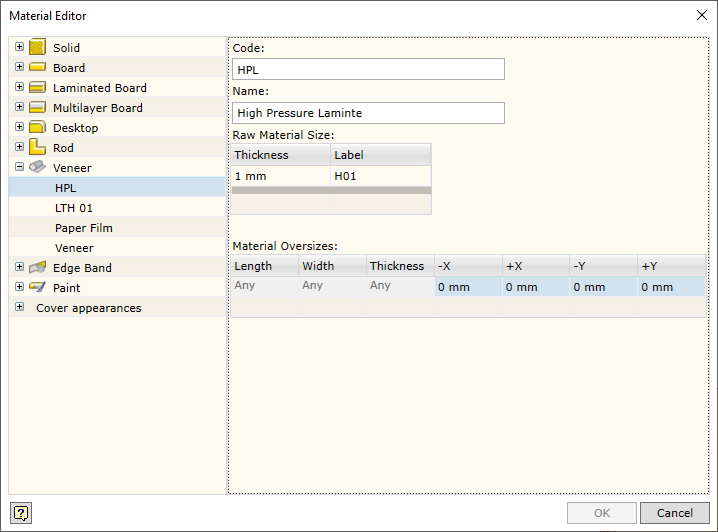

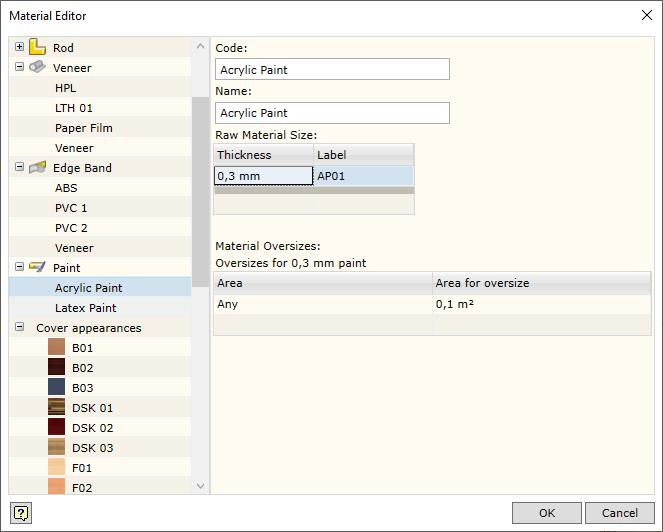

On the left side of the window of material editor, you will find database browser presented in the form of a drop-down tree structure. On the right side, you will find editing window for the active item, i.e. the item constructor (zone 4).

The browser tree has three levels:

1.Material type level.

2.Material level.

3.Material thickness level. This level allows differentiating the materials according to thickness (thickness range), if necessary. By default, CAM technology processing settings for any material thickness are used. If necessary, thickness range may be specified for materials, and different CNC processing settings may be used for each range. Placing the cursor on part thickness opens an additional window on the rights side of the dialogue for entering CAM technology settings. Information about the settings is available here.

4. Dialogue zone. It is used to display and edit the properties at the selected level.

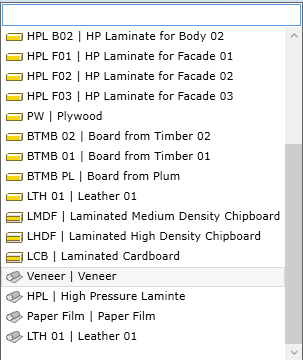

All Woodwork for Inventor materials are categorized into the following types:

▪Fill materials: ✓Solid ✓Board ✓Laminated Board ✓Multilayer Board ✓Desktop ✓Rod

▪Cover materials: ✓Veneer ✓Edge Band ✓Paint

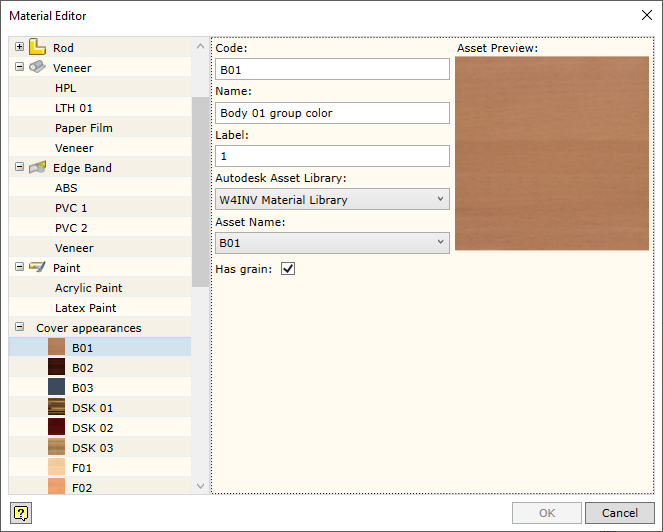

The last level row contains a group of the available cover appearances in which all colors that can be linked to materials are entered.

The following materials have different colors: 1.Laminated board 2.Multilayer board 3.Desktop 4.Veneer 5.Edge band 6.Paint

Click here for more information.

|

The second level of the tree structure contains items belonging to the expanded group. If you place the cursor on this item on the right side of the window, you will see a constructor of this item. Its form depends on the type of item being created or edited.

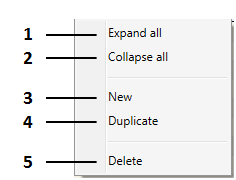

Each item has a contextual menu with the help of which items are controlled. It can be opened by right-clicking on it.

1.Full expansion of the tree structure. 2.Full collapse of the tree structure. 3.New item creation. 4.Item copying. 5.Item deletion.

|

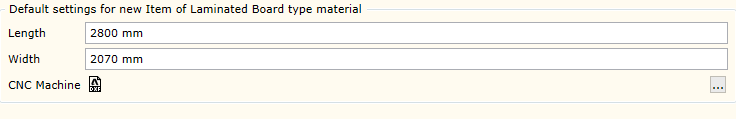

Each material type has a setting editor, which allows editing parameters that are automatically applied when creating new items for the given materials. Once the material has been created, the user can edit the assigned settings for each individual material.

The following settings can be edited:

1.Setting the size of a raw material sheet. 2.Selecting CNC machine(s). The order in which CAM Solver will create CNC jobs depends on the order of selecting the specific machine (which one is first and which one is subsequent).

|

The entire Woodwork for Inventor material representation mechanism is based on the Autodesk Inventor material and color libraries. The Woodwork for Inventor add-on is provided along with its database (W4INV Material Library) which is an Autodesk Inventor Asset type database. In addition to this, Woodwork for Inventor has its own database which contains items about Woodwork for Inventor material properties. In addition, each fill material is linked to Autodesk Inventor Asset Material, whereas a cover material is linked to Autodesk Inventor Asset Appearance. The user can create his own libraries of Autodesk Inventor materials/colors and use them in creating items in his Woodwork for Inventor database.

To use your own Autodesk Inventor material data base, you have to register this base in the project file (click here for more information). Then a readily available data base created by the user will appear in the Woodwork for Inventor material data base selector (see dialog description) the items of which can be used when defining a material or color.

|

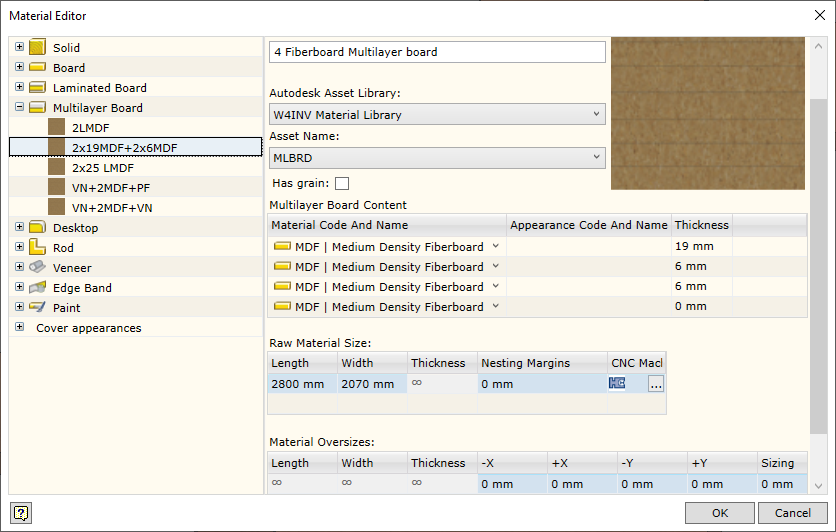

The multilayer board constructor differs from a regular fill material constructor because this material consists of other materials. In the Multilayer Board Content table, you can construct the composition of a multilayer board.

When creating a multilayer board, the following rules are to be observed:

▪A multilayer board can only consist of the following types of materials: ✓Board ✓Laminated board (has a color) ✓Veneer (has a color) ✓Paint (has a color) ▪A multilayer board cannot consist only of cover type materials. ▪A material that possesses a color can only be inserted in the top or bottom layers. ▪If a material having a color is inserted in the bottom, then a color-linked material must also be inserted in the bottom. ▪All layers have thickness, except for one that is made from a fill material and has a thickness equal to 0. It is called a layer of “floating” thickness. It means that the thickness of this layer will be calculated by summing up the thicknesses of all layers and by subtracting this sum from the thickness of the part model.

If the above rules are not observed, Woodwork for Inventor will not allow the entry of such materials or such material changes.

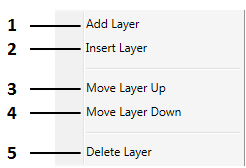

Each item has a contextual menu:

1.Adding a layer. Inserts a board type material which can later be replaced by a different one, observing the above rules. 2.Inserting a layer above the current row. Operates in the same principle as the layer addition. 3.Moving the layer up by one row. 4.Moving the layer down by one row. 5.Layer removal.

|

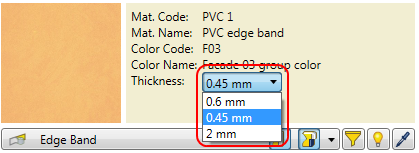

If you have entered several thickness values, you can select a desired value in the material assignment dialog.

|

|

|

|