Multilayer boards are composed from top/bottom covers of regular boards. These components have to be quickly assembled in the assembly phase and the material can be used only once in the assembly. Therefore, the material of a multilayer board can be:

| 1. | Created in the Woodwork for Inventor material database and used for the assembly of multiple items. Such material will be called global. |

| 2. | Created as a Woodwork for Inventor material when assembling specific parts of an item. The information of such material is stored with a particular part. Such material will be called local. |

A global material is created and stored using the Woodwork for Inventor database editor.

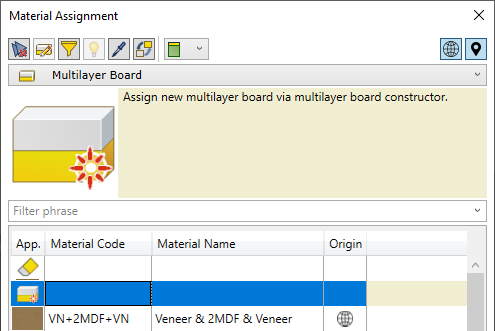

Another, more convenient and visual way to create global/local multilayer boards is using the multilayer board assembler, which can be opened from the multilayer board material assignment command.

The multilayer board material assembler can be accessed from the list of materials for multilayer board material assignment (next to material deletion function). ![]() .

.

Multilayer board material assembler is opened by selecting at least one part of the item and clicking "Apply".

The assembler dialogue box is then displayed.

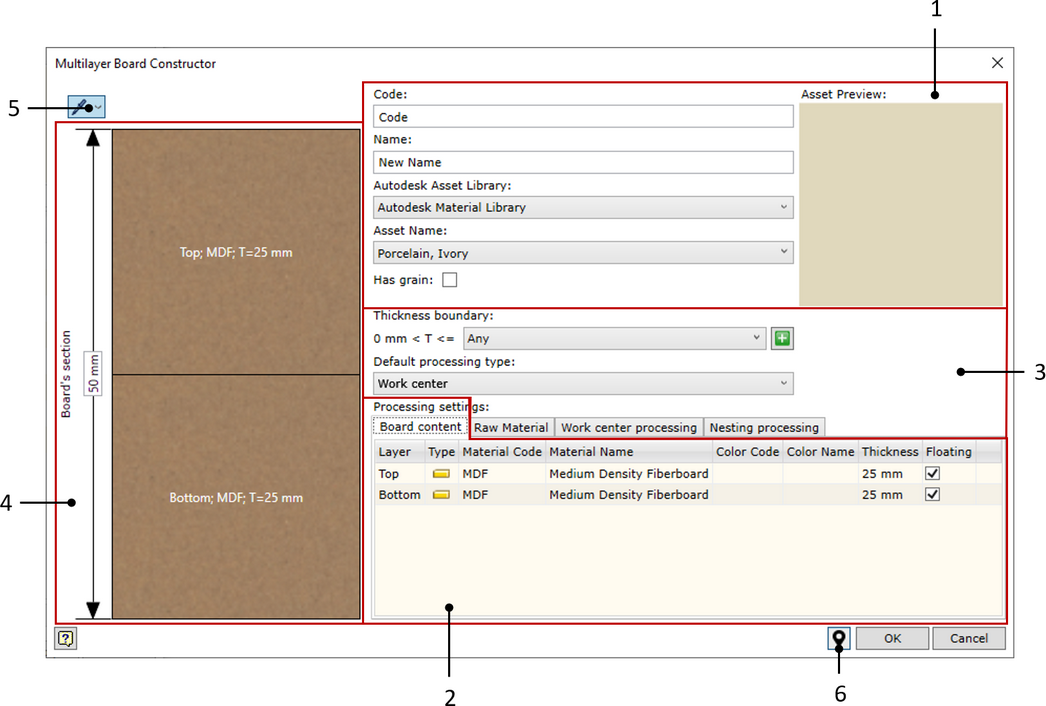

The dialogue box can be divided into the following functional sections:

| 1. | Section of material code, name and linking with Autodesk Inventor material. |

| 2. | Section of assembly of material layers. Additional cards are provided for describing additional characteristics of materials: |

| a. | Board content: a table showing the components of the assembled material. Left click of the mouse calls up a context menu, which allows manipulating the material layers: adding or removing a layer, etc. It also shows the thickness of the layer achieved when assembling the material. Cover materials always have a thickness, which is selected from the materials database. For other layers the user can choose one of the following: |

| i. | Floating: automatic calculation of layer thickness. Thickness of hard-set layers are deducted from the thickness of the part and the result is divided between the thicknesses labeled as Floating. |

| ii. | If the Floating label is disabled, the user can specify the desired thickness of the board. Remember that a material must have at least one floating layer. Otherwise the board assembler will not accept the description of material. |

| b. | Raw Material Size: dimensions of raw material board. These dimensions are used by default if the part of such material has to be cut using a nesting CNC machine. |

| c. | Oversizes: allows setting oversizes for automatically assigned materials of parts, which will be cut from such materials. |

3. Specifying CAM technology settings for this multilayer material. It matches the description for the material group.

4. This section contains graphical display of the board composition. The thickness of the board under assembly is displayed next to it. The user can enter this value himself/herself or read it from the model by clicking the button. ![]() .

.

5. The properties of a part are read upon showing the desired part on the graphical display. The drop-down menu allows selecting the properties of the material of the existing part to be transferred to the assembler. Here, you can read:

| a. | Preliminary thickness: thickness of the part. By the way, this parameter is read in any case. |

| b. | Asset: all information related to the assignment of material in Autodesk Inventor. |

| c. | Board Content: if the part already has a multilayer material, its content will be shown in the assembler. |

| d. | Raw Material Size: if the part already has a multilayer material, the properties of the raw material board will be included in the information processed by the assembler. |

| e. | Oversizes: just like with the previous point, automatic oversize assignment information will be included in the processed information. |

6. Globally/locally saved material.

| a. |

| b. |

Let us say that the user assigned the board material to the part during assembly and then added the selected cover material on both sides of the part. This is a standard course of work with Woodwork for Inventor. However, the user can see that such composition is needed not only for a single part, but may be used in other parts or items as well. In such case, the user can read the material and cover materials of the part and automatically create the content of the multilayer board assembler. This can be done by using the multilayer board assembler. The instructions for this are given in this video.

|

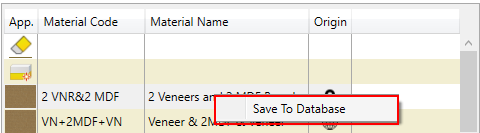

In order to create a local material to be used with other assemblies, it must be made global. To do this, click on the item of the desired local material in the material assignment dialogue box to open the context menu.

|

Multilayer materials can be edited using the multilayer board material editor. To do this, select the item of the desired material in the material assignment command and click

|